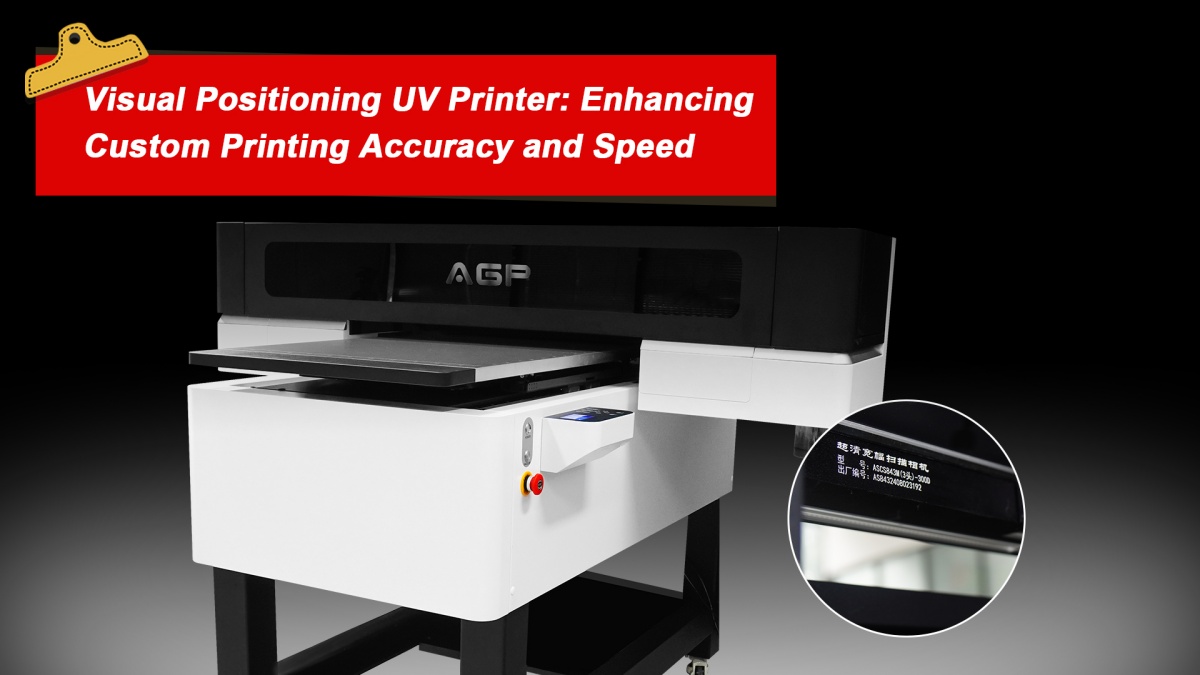

Visual Positioning UV Printer: Enhancing Custom Printing Accuracy and Speed

The advent of visual positioning UV printers has transformed the landscape of modern printing, especially in industries demanding high accuracy and efficiency. This innovative technology allows UV printers to automatically detect the position of substrates on the printing platform, enabling precise alignment and reducing human error. If you're in the printing business, understanding how a visual positioning UV printer works and its benefits can help you stay ahead in this competitive market. Here’s a detailed look at what this cutting-edge printer can do.

What is a Visual Positioning UV Printer?

A UV printer uses UV-curable inks that are instantly cured by UV light during the printing process. This method ensures high durability, quick drying, and vibrant colors, making it a popular choice for printing on various materials like glass, wood, and metal. The visual positioning UV printer is an upgraded version of traditional UV printers, equipped with a high-resolution camera and advanced software for automatic alignment. It scans the surface of materials, identifies their precise location, and adjusts the printing design accordingly to ensure perfect positioning every time.

How Does a Visual Positioning UV Printer Work?

The workflow of a visual positioning UV printer involves a few straightforward steps:

-

Designing the patterns: Create the design on a computer.

-

Placing the items: Randomly position the items on the print bed.

-

Scanning the surface: The printer uses its visual positioning system to scan the item’s surface, detecting its shape and orientation.

-

Alignment confirmation: The control software aligns the design with the exact position of the item.

-

Printing process: Once aligned, the printer starts printing, achieving accurate and high-quality results.

Benefits of Using a Visual Positioning UV Printer

This advanced technology delivers exceptional results, offering a wide range of advantages for businesses. Let’s explore why it’s becoming an essential tool for high-quality printing needs.

1. High Precision

With the visual positioning system, the printer can automatically align the design to the exact spot on the material, ensuring accuracy without manual adjustments. This significantly reduces the chances of human error and improves overall precision.

2. Great Efficiency

Automating the alignment process drastically cuts down on production time. The system operates swiftly, ensuring that printing jobs are completed quickly, without compromising quality.

3. Versatile Applications

Whether the substrate is flat, cylindrical, or irregularly shaped, the visual positioning UV printer is designed to handle all types of surfaces with ease. This versatility opens up new possibilities for industries looking for diverse printing options.

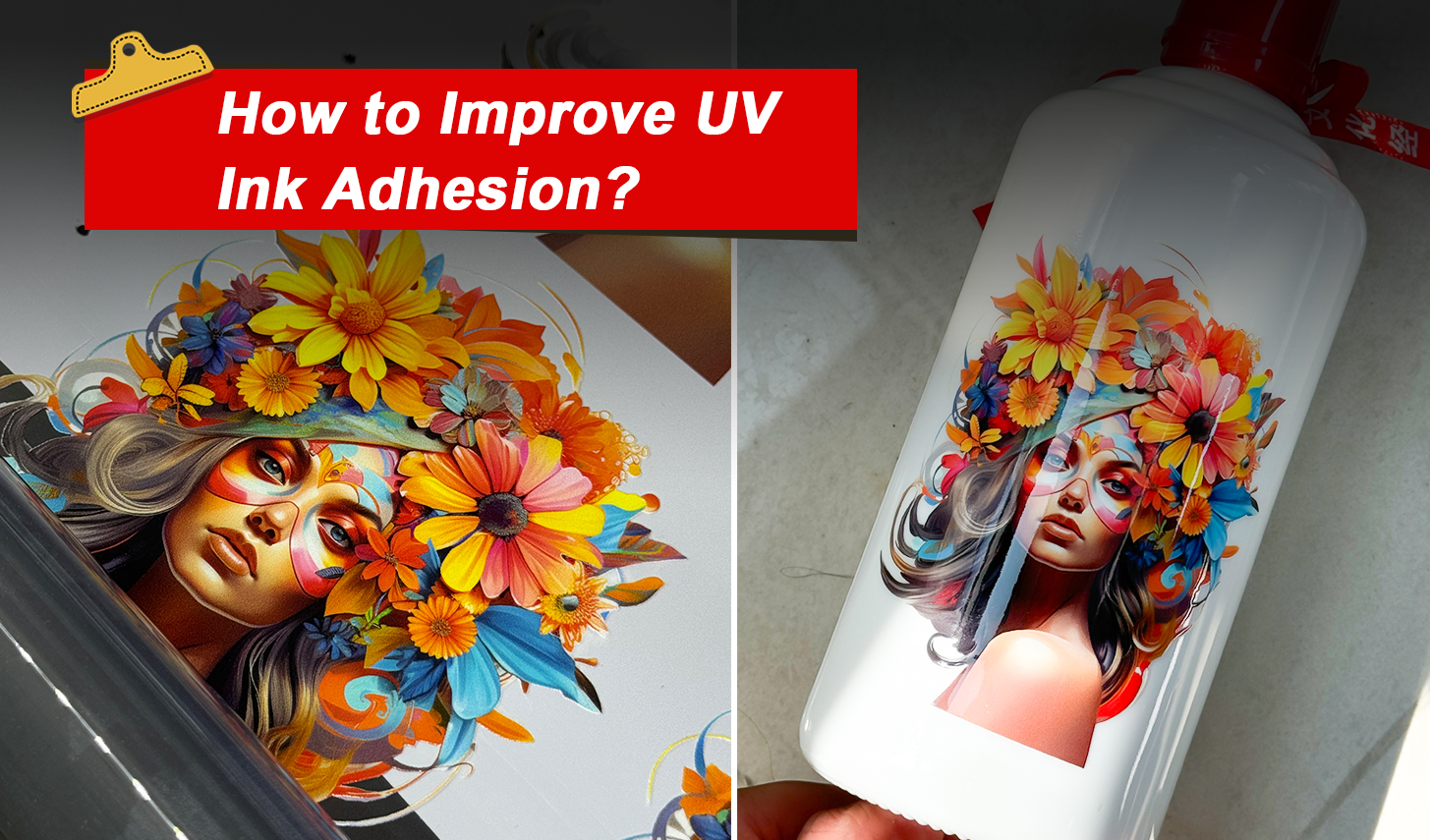

4. Eco-Friendly Printing

The printer’s precise alignment reduces waste by ensuring every print is perfectly positioned. This not only conserves material but also reduces ink usage, contributing to a more sustainable production process.

5. Ideal for Mass Production

For large-scale operations, the visual positioning UV printer offers uniformity and consistency across multiple prints, making it a highly reliable option for mass production, ensuring all orders are delivered on time.

Applications of Visual Positioning UV Printer

The visual positioning UV printer is highly versatile and suitable for a variety of printing applications. Below are some common uses in modern industries:

Personalized Items

From custom phone cases to keychains, a visual positioning UV printer can precisely print personalized designs, ensuring the alignment is perfect every time. This is ideal for businesses that specialize in offering customized products.

Packaging Items

Whether it's for boxes, bottles, or cosmetic packaging, precise printing on packaging materials is essential for brand identity. The visual positioning UV printer ensures that logos and labels are accurately applied, enhancing the product's appeal.

Promotional Items

Companies often use promotional items for marketing purposes, and the visual positioning UV printer ensures that these items, whether pens or tote bags, have consistent prints across large orders, making them highly efficient for bulk production.

Conclusion

In conclusion, the visual positioning UV printer stands as a game-changer in the printing industry. With its advanced alignment technology, this printer brings precision, speed, and eco-friendly benefits to businesses, helping them stay competitive in the ever-evolving market. Whether you’re creating personalized gifts, packaging, or promotional products, this printer guarantees exceptional results, making it an indispensable tool for high-quality and mass production printing.

Ready to enhance your printing process with the latest in visual positioning technology? Contact AGP today for expert advice and recommendations tailored to your needs.