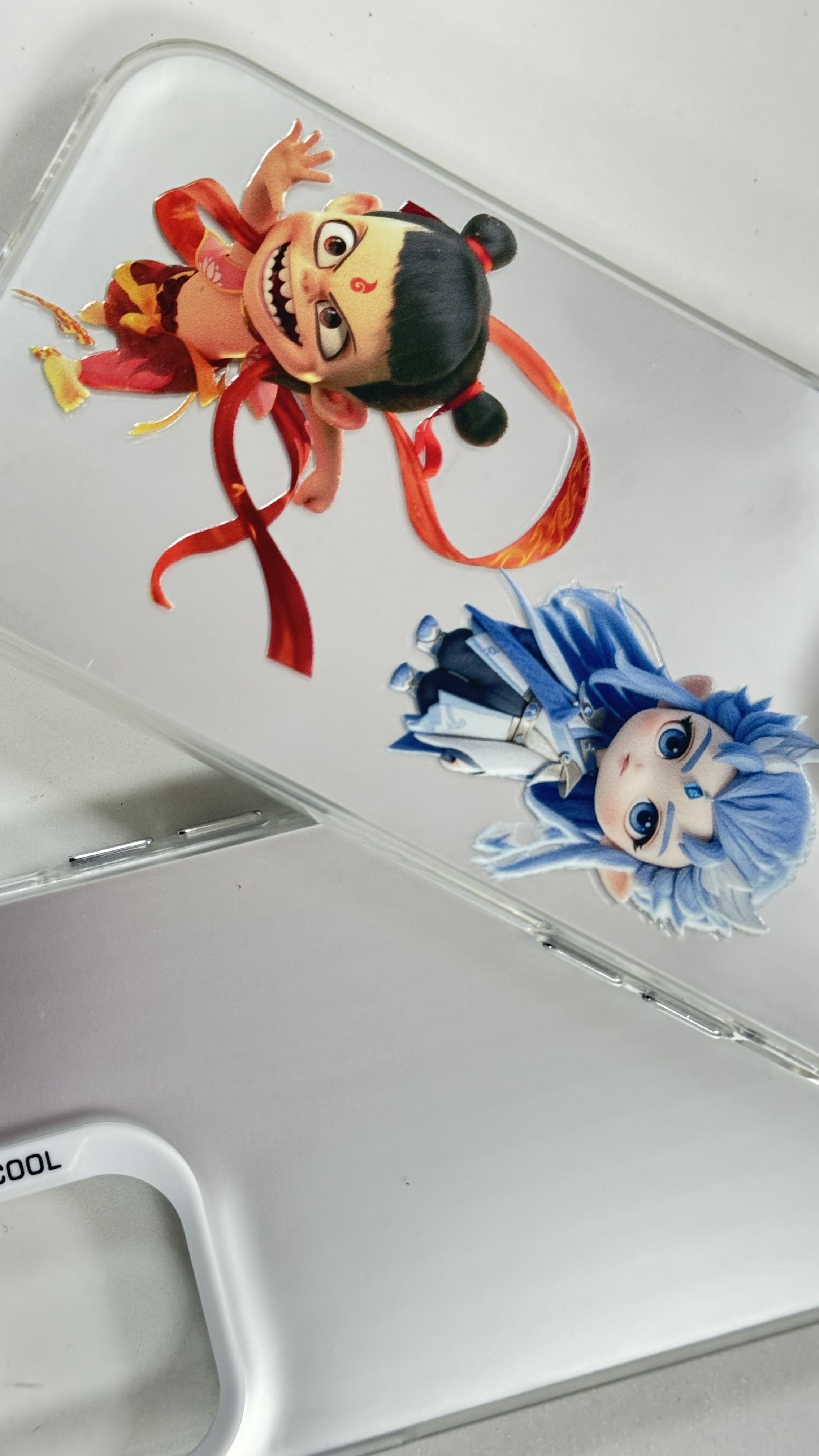

Phone Cases

UV DTF printing is a two-step process where the design is first printed onto a special release film using UV-curable inks, including white and varnish layers. This printed film, known as a crystal label, is then transferred onto the desired object—such as a phone case—through manual application. The result? A high-resolution, glossy, and textured print that adheres firmly to a wide variety of materials.

This technology eliminates the need for heat pressing or pre-coating, making it ideal for intricate surfaces and items that can’t be laid flat, like silicone, TPU, leather, acrylic, and even metal phone cases.

How to Make Custom Phone Cases with UV DTF Crystal Labels

Here’s a simplified breakdown of the production workflow using a UV DTF printer:

1. Design Preparation

Start by creating your custom design using graphic software. Whether it's a photo, brand logo, anime artwork, or a couple’s image, you can include full-color elements, white ink layers, and varnish highlights for a 3D textured look. RIP software helps prepare the file for accurate output.

2. Print on the Transfer Film

Load the UV DTF printer with the crystal transfer film. The printer lays down the image in reverse order—CMYK, then white, then varnish—curing each layer instantly with UV light. This results in a glossy, embossed label ready for transfer.

3. Apply to Phone Case

Peel off the printed film and place it onto the phone case surface. Gently press to ensure good adhesion and remove the backing film. No heat press or additional finishing is required. The print appears instantly vibrant and professionally finished.

Why Choose UV DTF for Phone Case Printing?

● Wide Compatibility

From flexible silicone to hard plastic, and even textured leather, UV DTF crystal labels adhere strongly to a variety of phone case materials. This adaptability makes it a preferred choice for producers handling multiple product types.

● Eye-Catching Visual Effects

Thanks to the combination of white ink and varnish, the final prints offer a glossy, layered texture that enhances the perceived value of the product. Ideal for designs that require visual pop or luxury finishes.

● Fast and Scalable

The film printing process allows you to batch-produce designs and stock them for on-demand application. This streamlines production for businesses handling custom orders or retail fulfillment.

● High Durability

Once applied, UV DTF prints are scratch-resistant, waterproof, and fade-resistant—perfect for daily-use items like phone cases that face frequent handling.

Popular Applications of UV DTF Phone Case Printing

-

Personalized Cases: Photos, names, pet portraits, or couple designs

-

Brand Merchandise: Logos and slogans for influencers or companies

-

Artistic Creations: Cultural or retro designs with high-definition detail

-

Promotional Gifts: QR codes or advertisements printed for giveaways

Is UV DTF Printing Right for Your Business?

If you're seeking a cost-effective, high-quality method to enter the booming custom phone case market, UV DTF printers offer an excellent starting point. They combine industrial efficiency with boutique-level personalization, empowering you to serve both large batch orders and one-off customizations.

Whether you're a gift shop owner, a custom merch brand, or a print-on-demand startup, UV DTF technology can help you unlock your full creative potential—without the limitations of direct substrate printing.

Ready to get started? Explore AGP’s range of UV DTF printers and crystal film solutions to bring your phone case business to life with vibrant results that stick.