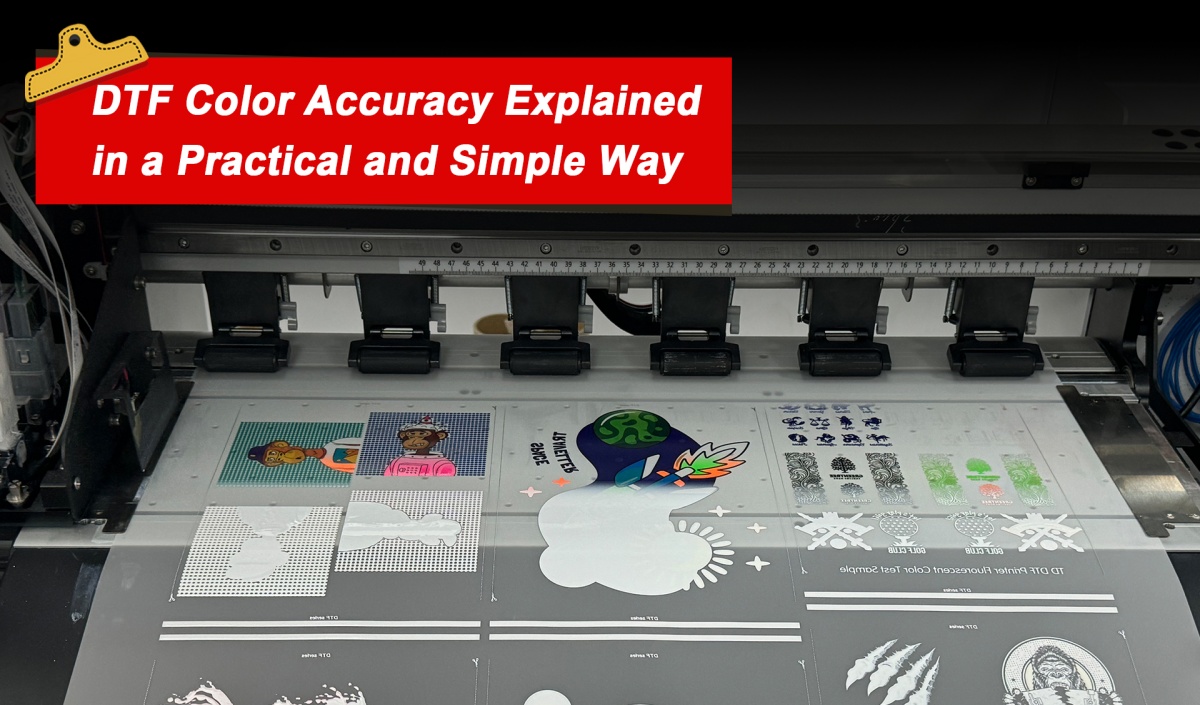

DTF Color Accuracy Explained in a Practical and Simple Way

Direct-to-film printing has become a popular choice for clothing brands and print shops because of its clarity and rich colors. As more small businesses adopt this method, one challenge appears again and again. Many users struggle to achieve stable and accurate colors. This happens even when good films, inks, and printers are used.

Color issues can quickly affect product quality. A print that looks perfect on a screen may appear dull or overly bright once transferred to fabric. Readers who want more consistent results often look for clear and simple guidance. This article explains how DTF color accuracy works and how anyone can improve it through optimal settings, proper equipment care, and safe printing practices.

Understanding DTF Printing Technology

DTF printing is a simple process: you send the design to the printer, and it puts the ink onto a special film. After that, the film is dusted with a light layer of powder so the ink can grip the fabric once heat is applied. The steps look easy from the outside, but the way the colors actually form depends on a lot of tiny things happening inside the machine that you don’t really see.

The printer uses CMYK ink to make the colors shown on the screen. Each of these channels plays a role in how the final image looks. The film receives ink differently from normal paper, so the printer must give the right amount of ink for each color. If the printer releases too much or too little, the colors may change, and your print will become a disaster.

Why the DTF Process Affects Color

The film changes with humidity, room temperature, and even the amount of ink. All of these things influence how fast the ink settles and how well it sticks to the fabric afterward. When any of these conditions change, the printed colors may appear lighter or darker than expected. This is why color accuracy in DTF printing depends on a balanced workflow rather than a single step.

Factors Influencing Color Accuracy in DTF Printing

Even experienced printers face color shifts at times. Understanding the main factors makes troubleshooting easier.

Ink Quality and Consistency

DTF ink needs to be smooth, stable, and fresh. Ink that contains clumps or has been exposed to air for too long may produce uneven colors. Low-cost ink can also have fewer pigments, which results in flat or faded prints.

Film Quality

Some films absorb ink better than others. A high-tension film supports the ink evenly, which helps the colors remain stable. If the film has an uneven surface or reacts poorly in humid weather, the print may show color dots or soft edges.

Printer Settings

Colors depend on the settings of the printing software. Wrong profiles or saturation levels, or sizes, can cause a major color change. Even a little change in these settings can make red into orange or blue into purple.

Environment and Humidity

DTF printing needs a controlled space. If the air is dry, the ink dries faster, and the colors look lighter. But if the air is too humid, the film absorbs extra moisture, making the colors dark.

Techniques to Improve Color Precision

Use the Correct Color Profiles

A profile tells the printer how to do shades in the design. When the right profile is selected, the printer knows the right amount for every part. Many software systems allow users to import profiles that match the film and ink. This simple thing often corrects major issues.

Calibrate the Monitor

The monitor should be calibrated. A calibrated screen shows colors as real, so the printer gets more accurate input.

Maintain the Printer Head

Printer heads collect small amounts of pigment over time that dry up. Regular cleaning prevents blockages. When color flow remains consistent, the final print has sharper edges and more predictable shades.

Store Ink Properly

Keep the ink at a steady temperature. Sudden changes may cause thickening or separation. When ink is stored correctly, the color flow remains stable and the printed result becomes more reliable.

Common Challenges in Achieving Accurate Color

Even with good practice, issues still appear at times. These are the problems most users face.

Incorrect Whites or Washed-Out Colors

This often happens when too little ink is used or when the software lowers the saturation. Sometimes the white layer behind the design is too strong, pushing other colors forward and creating an unnatural look.

Prints That Appear Too Dark

Dark prints usually form when the ink layer is too thick. This may happen when the printer speed slows down or when the print passes over the same area twice. Humid conditions also darken prints.

Color Differences After Heat Pressing

A design may look perfect on the film, but change once pressed onto fabric. Heat can brighten, fade, or shift colors if the temperature is not correct. Some fabrics absorb pigments more deeply, resulting in slight changes in color tone.

Banding and Uneven Lines

Banding happens when one color channel releases less ink than expected. This creates light lines across the print. A quick nozzle check and cleaning usually corrects this problem.

Conclusion

Achieving good DTF color accuracy is possible for anyone who understands the factors that influence color formation. The printer, the ink, the film, and the working environment all shape the final result. By choosing stable materials, maintaining the printer head, selecting the right profiles, and controlling the printing space, users can improve their color reliability in a consistent way.

Small adjustments often produce noticeable changes. With regular practice and careful setup, DTF printers can deliver clear, balanced, and professional-looking colors for every project.