Can the UV DTF Printer also support the Gold stamping adhesive sticker solution?

Gold stamping, also known as hot stamping, is a common decorative process in the packaging and printing industry. The Gold stamping label adhesive sticker solution uses the principle of heat transfer to imprint the aluminum layer from electrochemical aluminum onto the substrate's surface, creating a distinctive visual effect. After special treatment, it can maintain stable quality in harsh environments such as dry ink powder and dust. Labels are widely used and are also an effective way to increase the added value of products.

About the gold stamping process

The Gold stamping adhesive sticker process is divided into two types: cold stamping and hot stamping.

The principle of cold stamping mainly uses pressure and special glue to combine anodized aluminum with the base material. The entire process requires no heating and does not involve hot stamping plates or padding plate technology. However, the cold stamping process started late, and it consumes a considerable amount of electrochemical aluminum during the hot stamping process. The glossiness of electrochemical aluminum after cold stamping is not as good as hot stamping, and it cannot achieve effects like debossing. Therefore, cold stamping has not yet formed a significant application scale domestically. Currently, most mature printing companies in the market still use hot stamping technology for better hot stamping effects.

The gold stamping adhesive sticker can be divided into pre-hot gold stamping and post-hot gold stamping. Pre-hot gold stamping refers to gold stamping on the label machine first and then printing; and post-hot gold stamping refers to printing first and then gold stamping. The key to them is the drying of ink.

①Pre-hot gold stamping process

When using the pre-hot gold stamping process, since the ink used is oxidative polymerization drying type, it takes a certain amount of time for the ink layer to dry completely after printing, so the gold stamping pattern must avoid the ink. The best way to avoid ink is to pre-gold stamp the roll material and then print it.

The use of the pre-hot gold stamping process requires that the printing pattern and the gold stamping pattern are separated (side by side), because the surface of the anodized aluminum is smooth, ink-free, and can not be printed on.

Pre-hot gold stamping can prevent ink from smearing and ensure the quality of label printing.

②Post-hot gold stamping process

The post-hot gold stamping process requires the roll material to be printed with patterns first, and the ink is instantly dried through a UV drying device, and then gold stamping is achieved on the surface of the material or ink after the ink is dried. Since the ink has dried, the gold stamping pattern and the printed pattern can be printed side by side or overlapping, so there will be no ink smearing.

Of the two gold stamping methods, pre-hot gold stamping is the more ideal method. It also brings convenience to label pattern design and expands the application range of gold stamping patterns.

Features of gold stamping adhesive labels:

1. Support personalized customization

Different materials and gold stamping effects can be flexibly selected, and the gold stamping accuracy is high to meet the different needs of customers.

2. Strong aesthetic appeal

The color is bright, with different color gradients under different lighting conditions, the details are lifelike, and the product is smooth and shiny.

3. Environmental protection and safety

Printed with water-based ink, it will not cause pollution to the environment. At the same time, the label itself will not produce chemical pollution and fully comply with the production standards of food, pharmaceutical and other industries.

4. The product has strong applicability

Hot stamping self-adhesive labels can be applied not only to flat product labels, but also to three-dimensional object surfaces. It can maintain good adhesion even on irregular surfaces such as curves and rounded corners, and can be used in food, cosmetics, medicine, electronics and other industries as well as various gifts, toys, bottles, cosmetic packaging, barreled products and many other fields.

Generally speaking, gold stamping adhesive labels are high-quality, personalized labels.

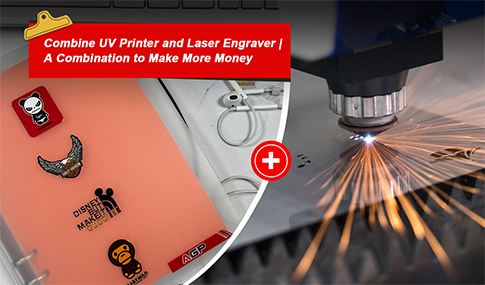

AGP UV DTF printer (UV-F30&UV-F604) can not only print finished UV labels, but also directly produce gold stamping adhesive solutions. Using existing equipment components (no need to add additional devices), you only need to replace the adhesive consumables-matching ink and roll film, and you can achieve adhesive printing, varnishing, gold stamping, and lamination in one step. It is a versatile and cost-effective machine!

More product applications are waiting for you to explore!