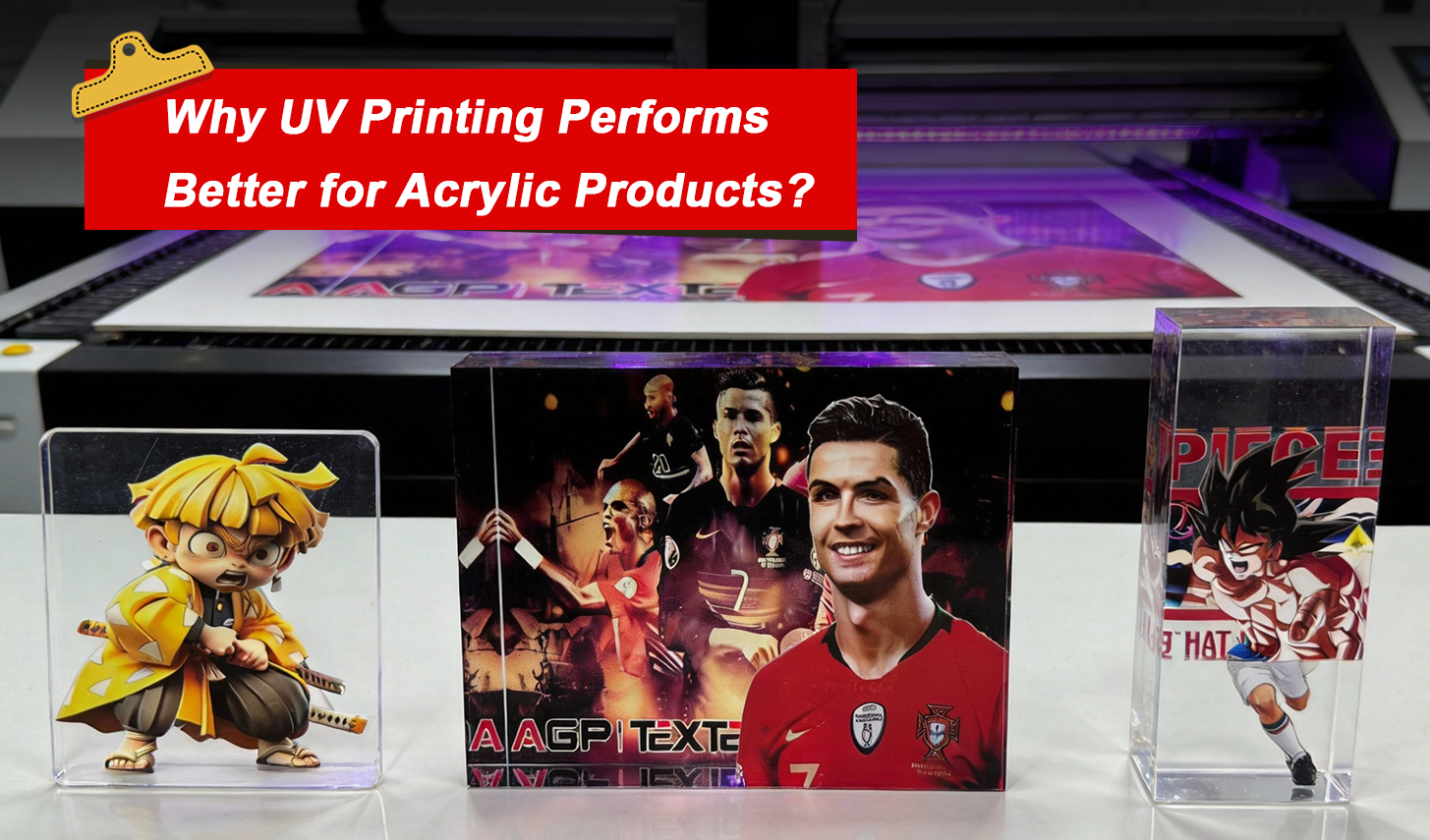

Why UV Printing Performs Better for Acrylic Products?

In today’s highly competitive customization market, acrylic products have become one of the most popular categories across retail, branding, gifts, and décor. From acrylic signs and displays to keychains, badges, and decorative panels, acrylic is everywhere—especially among younger consumers who favor clear, glossy, and modern aesthetics.

As demand continues to grow, printing businesses are continually evaluating which printing technologies deliver the best quality, efficiency, and profitability. Among all available methods, UV printing and screen printing are the two most commonly used solutions for acrylic production.

But when it comes to DTF prints–driven customization trends, fast turnaround requirements, and small-batch personalization, one question keeps coming up:

Which printing method truly works better for acrylic products?

This article delves into the intricacies of acrylic UV printing and screen printing, exploring why UV printing has become the preferred solution for modern acrylic customization.

Acrylic UV Printing vs Screen Printing: Basic Definitions

What Is Acrylic Screen Printing?

Screen printing on acrylic is a traditional process that uses a mesh screen and a squeegee to transfer ink onto the acrylic surface. Each color requires a separate screen, and the ink is pushed through the mesh openings to form the desired pattern.

Due to its relatively simple operation, acrylic screen printing has long been used for basic signage and large-volume production of simple designs.

However, as customization trends shift toward DTF prints, multi-color designs, and short-run orders, the limitations of screen printing have become increasingly obvious.

What Is Acrylic UV Printing?

Acrylic UV printing uses a UV flatbed printer to print images directly onto the acrylic surface. UV inks are instantly cured by ultraviolet light, allowing the ink to bond tightly with the material.

Unlike screen printing, UV printing requires no film plates, no color separation, and no manual setup. Designs are sent directly from the computer to the printer, making it highly suitable for digital customization and on-demand production.

Key Differences Between Acrylic UV Printing and Screen Printing

1. Cost Structure

Screen printing involves high upfront costs due to plate making. Each design—and each color—requires a separate screen. This significantly increases costs when handling multi-color images or small-batch orders.

UV printing, on the other hand, eliminates plate-making. Whether printing one piece or hundreds, the cost remains stable. For businesses expanding into DTF prints, custom acrylic gifts, or branded products, UV printing is far more cost-efficient.

2. Color Performance and Design Flexibility

Screen printing is best suited for solid colors and simple graphics. Gradient colors, photographic images, and fine details are difficult—or impossible—to achieve without complex overprinting.

UV printing excels at full-color images, gradients, textures, and high-resolution details. This makes it ideal for modern designs inspired by DTF prints, where vibrancy and detail accuracy matter.

3. Durability and Outdoor Resistance

Screen printing inks contain curing agents that help ink adhere to acrylic surfaces, but long-term outdoor exposure can still cause fading or wear.

UV inks provide superior adhesion, scratch resistance, and UV resistance. Acrylic UV prints remain vibrant even under harsh outdoor conditions, making them suitable for signage, displays, and promotional applications.

Why Acrylic UV Printing Is the Better Choice

When comparing long-term performance, production efficiency, and market adaptability, UV printing clearly outperforms screen printing for acrylic products.

Screen printing struggles with customization, color limitations, and rising labor costs. UV printing aligns perfectly with DTF prints–inspired personalization trends, digital workflows, and fast-changing customer demands.

For businesses looking to stay competitive, UV printing is no longer an upgrade—it’s a necessity.

How to Print on Acrylic Using a UV Printer

Printing acrylic products with a UV flatbed printer is straightforward and efficient:

Step 1: Design Preparation

Create or upload your design and process it through RIP software to ensure correct color output and print layers.

Step 2: Acrylic Surface Cleaning

Clean the acrylic surface thoroughly to remove dust and oil for optimal ink adhesion.

Step 3: Material Placement

Position the acrylic sheet securely on the UV printer platform.

Step 4: Parameter Setup

Adjust printing settings such as resolution, ink density, and white ink layers.

Step 5: Printing & Curing

Start printing. UV curing happens instantly, producing a finished product with vivid colors and sharp details.

Advantages of UV Printing on Acrylic

High Production Efficiency

Instant curing allows faster turnaround, perfect for batch production and urgent orders.

Outstanding Print Quality

UV printing delivers high-resolution images, vivid colors, and optional 3D or embossed effects—similar to premium DTF prints.

Cost-Effective Customization

One UV printer can handle multiple product types without additional tooling costs.

Eco-Friendly Printing Process

UV inks contain no volatile organic compounds, making the process safer and more sustainable.

Wide Application Compatibility

From acrylic sheets to decorative panels, signs, and displays, UV printing adapts easily to market trends.

Popular Applications of Acrylic UV Printing

Home Décor Products

Acrylic photo panels and wall art with crystal-clear transparency and rich colors.

Advertising & Branding

Outdoor signs, promotional displays, and retail branding with long-lasting durability.

Commercial Signage

Office signs, directional panels, and branded acrylic boards.

Personalized Gifts

Custom acrylic keychains, phone cases, nails, and badges inspired by DTF prints aesthetics.

Real Acrylic UV Printing Examples by AGP

AGP has delivered a wide range of acrylic UV printing solutions, including:

-

Acrylic display plates with high-gloss finishes

-

LED acrylic art panels with layered visual depth

-

Custom acrylic branding products for retail and exhibitions

Each project demonstrates the flexibility and professional output of UV printing technology.

Conclusion: The Future of Acrylic Custom Printing

As customization trends continue to evolve alongside DTF prints, digital workflows, and on-demand production, acrylic UV printing stands out as the most future-proof solution.

With superior color performance, durability, cost efficiency, and creative flexibility, UV printing enables businesses to meet modern customer expectations while expanding into new markets.

AGP is a factory-direct supplier of UV printing solutions, offering professional technical support and reliable after-sales service. If you’re exploring new opportunities in acrylic customization, UV printing is the direction worth investing in.