Why DTF Printing Makes T-Shirts the Top Choice for Custom Apparel

In the past few years, the customized clothing market has undergone a major shift—brands, studios, and small garment businesses are rapidly adopting DTF printing as their go-to method for producing custom T-shirts. Thanks to its impressive print clarity, strong wash resistance, and compatibility with a wide range of fabrics, DTF shirts have become one of the most sought-after products in the personalized apparel industry.

This article explains why DTF printed shirts stand out, how the technology works, and how businesses can leverage DTF printing to meet growing customer demand.

What Are DTF Shirts?

DTF shirts refer to garments decorated using the Direct-to-Film (DTF) printing process. Instead of applying ink directly onto fabric like DTG printing, DTF printing uses a DTF printer to output the artwork onto a specialized PET DTF film. After that, hot-melt DTF powder is applied, cured, and then transferred onto the shirt using a heat press.

This process creates a flexible, durable, and vividly colored print layer that adheres tightly to cotton, polyester, blends, nylon, and many other fabric types. Compared with traditional screen printing or DTG printing, DTF printing offers higher versatility, faster turnaround, and more consistent output—three major reasons why DTF shirts are rising in popularity.

How Does DTF Printing Work?

Although DTF printing uses advanced digital technology, the workflow is surprisingly streamlined. The process usually includes the following steps:

1. Design Preparation

Artwork is created on a computer and processed through RIP software to ensure accurate color output and correct ink arrangement for DTF film printing.

2. Film Printing

A DTF printer prints the design onto PET film using CMYK + White DTF ink. The printed white layer creates opacity, allowing colors to remain rich on both light and dark fabrics.

3. Powder Coating

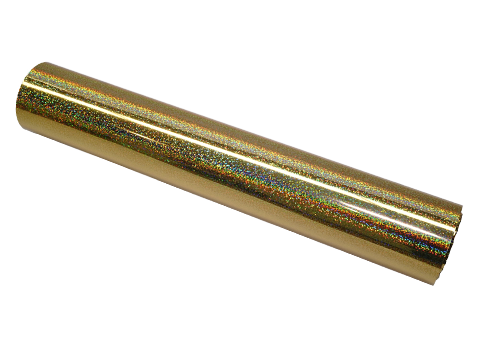

Right after printing, the wet ink is coated with DTF hot-melt powder. This powder forms the bonding layer that enables the artwork to fuse with fabric.

4. Powder Curing

The powder-covered film is heated in a curing oven, forming a smooth adhesive layer.

5. Heat Press Transfer

The cured film is placed onto the shirt and pressed with a heat press machine. After cooling, the transfer film is peeled away, leaving a soft, durable print on the fabric.

No pre-treatment liquids, no pretreat machine, and no fabric limitations. This simplicity is a major reason why both beginners and high-volume clothing brands prefer DTF.

AGP’s full range of DTF printers and DTF oven systems ensures consistent quality and high-efficiency output for all apparel businesses.

Advantages of DTF Shirts

1. Ultra-Sharp, High-Definition Prints

DTF printing produces crisp details, rich gradients, and bold colors—perfect for intricate logos, fine text, or multi-color artwork. The color vibrancy is comparable to DTG printing but more stable across different fabrics.

2. Compatible with Almost All Fabrics

DTF allows printing on:

-

Cotton

-

Polyester

-

Nylon

-

Spandex blends

-

Dark and light materials

Compared with DTG’s cotton-only limitations, DTF provides far more flexibility, making it particularly attractive to clothing brands and print shops.

3. Long-Lasting and Wash-Resistant

Properly applied DTF transfers resist:

-

Cracking

-

Peeling

-

Fading

-

Stretch deformation

Even after numerous wash cycles, DTF shirts retain their original vibrancy, making them ideal for daily wear, uniforms, and sports apparel.

4. No Pre-Treatment Needed

Unlike DTG printing, which requires pre-treatment and curing, DTF printing skips these steps entirely. The workflow becomes:

-

Faster

-

Cleaner

-

More cost-effective

This also reduces equipment investment and production complexity.

5. Eco-Friendly Ink & Reduced Waste

DTF printers use water-based DTF inks, which contain fewer harmful chemicals compared with solvent-based inks. The printing process generates minimal waste and aligns with global trends toward sustainable textile production.

Applications of DTF Shirts

DTF shirts are widely adopted in various industries due to their versatility and professional finish. Here are some top applications:

Personalized T-Shirt Design

From custom gifts and DIY apparel to matching couple shirts and family outfits, DTF printing makes one-off production affordable and efficient.

Corporate Branding

Businesses use DTF shirts for:

-

Staff uniforms

-

Event apparel

-

Company promotional clothing

DTF prints deliver sharp logos and long-lasting branding.

Independent Clothing Brands

Small designers love DTF because it supports:

-

On-demand production

-

Limited edition collections

-

Trend-driven micro-batches

Without minimum order quantities, designers avoid overstock.

Sportswear and Event Merch

DTF is ideal for:

-

Marathons

-

Concerts

-

Fan events

-

Festivals

-

School clubs

High-volume orders can be completed quickly with consistent quality.

How to Care for DTF Shirts

To extend the life of DTF-printed garments, simple maintenance habits work best:

-

Turn the shirt inside out before washing

-

Wash with cold water and mild detergent

-

Choose gentle machine cycles or hand wash

-

Avoid high-heat drying or ironing on the print

-

Do not use bleach or harsh chemicals

Following these steps helps maintain print elasticity and color accuracy.

Conclusion

DTF shirts have become a major trend in the custom apparel world because they deliver vivid colors, broad material compatibility, and reliable durability—all while simplifying production workflows. Whether you’re starting a T-shirt business, expanding apparel product lines, or producing branded merchandise, DTF printing provides a flexible and cost-effective solution.

AGP specializes in full-scale DTF printing solutions, including DTF printers, DTF ovens, A&B film, powders, and inks.

If you're ready to build or upgrade your T-shirt printing business, contact AGP to get a tailored DTF solution that fits your production needs.