Can UV Printers Effectively Print on Textiles?

UV printing has quickly become a revolutionary technology, renowned for its ability to print on a wide range of materials like metal, glass, plastic, and acrylic. With the rise of UV DTF (Direct-to-Film) and flatbed UV printers, it was only a matter of time before the question arose: Can UV printers print on textiles? In this article, we’ll explore this potential and highlight how UV printing technology is transforming the textile industry.

What is UV Printer?

A UV printer uses ultraviolet light to cure ink during the printing process, making it ideal for a variety of materials. UV printers come in different forms, including UV DTF printers, UV flatbed printers, and hybrid UV printers. The main advantage of UV printing lies in its ability to print vibrant, long-lasting designs on almost any surface.

The typical workflow of a UV printer involves designing patterns, printing them onto a substrate, and curing the ink with UV light. The result? Exceptional durability, vibrant color reproduction, and scratch-resistant prints that stand the test of time.

Why is UV Printer Gaining Popularity?

The popularity of UV printers in recent years can be attributed to several key advantages:

-

Unmatched Durability: UV-printed designs are resistant to wear, fading, and scratching, making them perfect for products that undergo frequent use.

-

Eco-Friendly: UV printing uses no solvents and generates less waste, making it an environmentally friendly option.

-

Speed: The instant curing process means no drying time, allowing businesses to meet tight deadlines without compromising on quality.

-

Versatility: UV printers can print on a wide variety of substrates, including textiles, wood, metal, glass, plastic, and more.

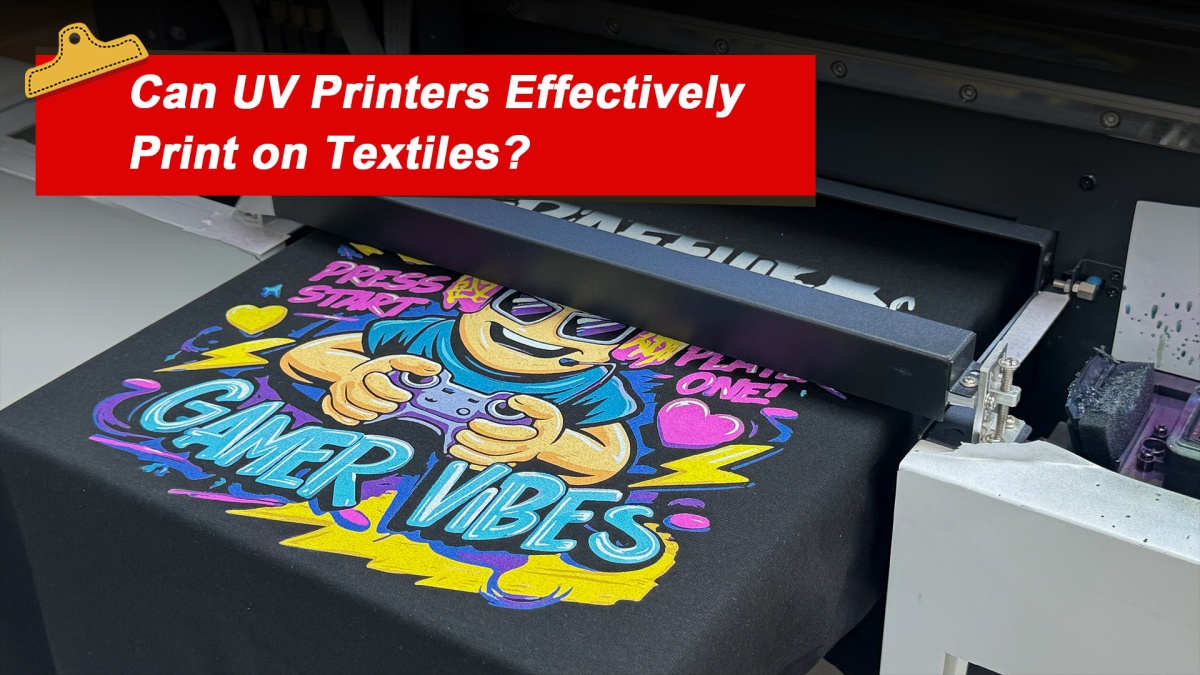

Can UV Printers Print on Textile?

Historically, UV printing on fabrics was a challenge, with traditional UV printers struggling to deliver satisfactory results on textiles. However, AGP’s UV printers have broken through these limitations. Now, with AGP's advanced UV DTF and flatbed printers, businesses can achieve high-quality, durable prints on textiles with impeccable detail.

Using UV DTF Printer for Textile Printing

One popular method for printing on fabrics with UV technology is through a UV DTF printer. This process involves printing silicone UV DTF stickers that can be heat-transferred to garments. The workflow looks like this:

-

Print patterns onto AB film using the UV DTF printer.

-

Transfer the printed design to fabric using a heat press.

-

Remove excess glue from the design.

-

Complete the final garment print.

This method is ideal for printing brand logos on clothing and is highly effective for producing small quantities of customized prints.

Using UV Flatbed Printer for Textile Printing

Another method of printing on fabrics is by using a UV flatbed printer. This approach is ideal for printing vibrant, scratch-resistant, and waterproof stickers that can be applied to clothing. Here's the process:

-

Print designs onto film using the UV flatbed printer.

-

Peel off the sticker and apply it to the fabric.

-

Use a heat press to fix the sticker onto the fabric.

-

Remove the film and finalize the garment.

This method is suitable for printing on both light and dark-colored textiles, and it delivers excellent color vibrancy and long-lasting durability.

Advantages of UV Printing on Textiles

-

Vivid Print Quality: UV printers create designs with exceptional detail, where every color and line pops with clarity.

-

High Efficiency: UV printing on textiles reduces production times and minimizes material waste, making it an efficient choice for high-volume printing.

-

Versatility: With the ability to print on both hard and soft materials, UV DTF printers can expand your business to different markets, such as custom apparel, home decor, and promotional products.

Conclusion: Embrace the Future of Textile Printing

With AGP's advanced UV DTF and flatbed printers, UV printing technology is now opening up exciting possibilities for textile applications. Whether you're printing on garments, bags, or accessories, UV printing can help you produce vibrant, durable designs that stand the test of time.

Expand your printing capabilities into the textile industry with AGP’s UV printers, and enjoy the benefits of high-quality prints, fast production, and environmentally friendly processes. Ready to learn more? Contact us today for a demo or to get more information on how UV printing can transform your textile printing business.