The Advantages of 3D UV Embroidery Stickers: Cost-Effective, Durable, and Flexible

For centuries, embroidery has been a symbol of quality and craftsmanship, giving textiles a luxurious, tactile feel. However, traditional embroidery often comes with significant limitations such as high costs, long production times, and restrictions on design complexity. Enter 3D UV embroidery stickers, a game-changing solution that brings the texture and high-end appeal of embroidery to the world of digital printing.

If you're a small business owner or a hobbyist looking to explore new possibilities for custom designs, 3D UV embroidery stickers open up a new realm of creativity. In this guide, we will walk you through the process, advantages, and various applications of 3D UV embroidery stickers, showcasing why this innovative solution is the perfect alternative to traditional embroidery.

What Are 3D UV Embroidery Stickers?

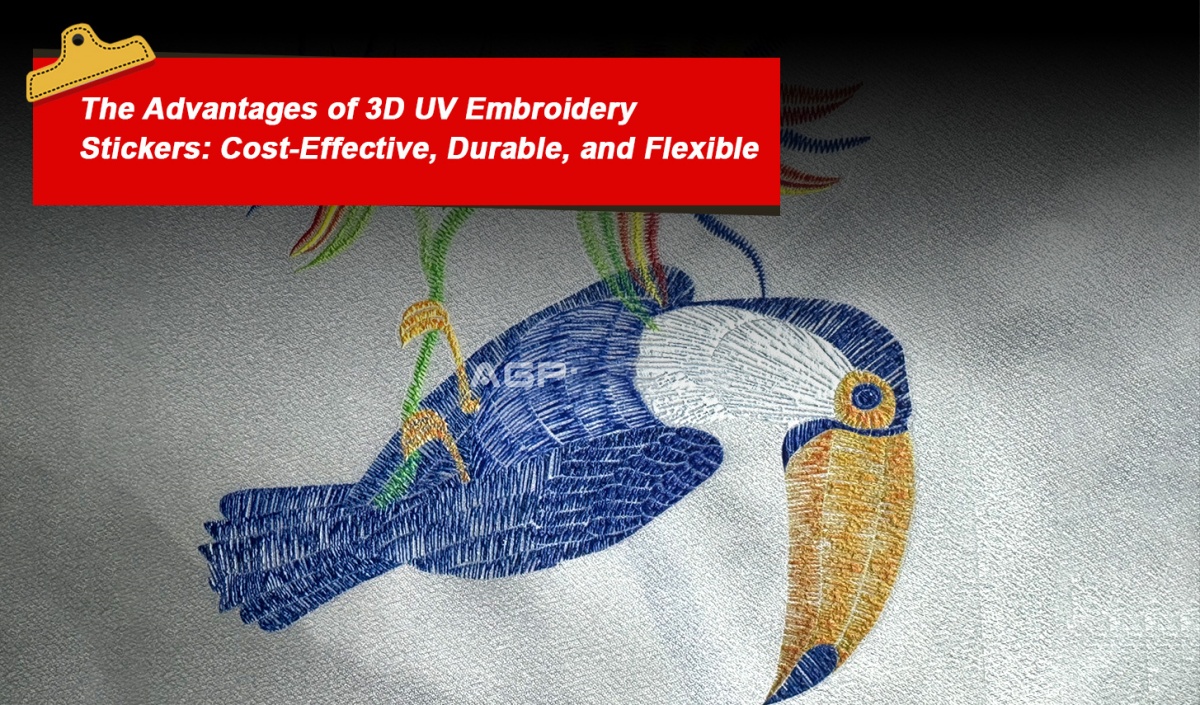

3D UV embroidery stickers are an innovative form of transfer that mimics the appearance and texture of traditional embroidery. Unlike flat prints or vinyl transfers, these stickers offer physical depth, creating a textured, raised effect that can be felt by hand, much like the surface of stitched embroidery.

The key technology behind these stickers is UV curing, which uses specialized inks to build up layers of material. These layers create a structure that replicates the look of woven fabric, making the sticker feel like a premium embroidered patch. They are durable, easy to apply, and versatile, offering a modern twist on classic embroidery.

Applications of 3D UV Embroidery Stickers

One of the most appealing aspects of 3D UV embroidery stickers is their versatility. While traditional embroidery requires specialized machinery and is typically limited to flat surfaces, these stickers can be applied to a variety of materials, including soft, rigid, and uneven surfaces.

Fashion and Accessories

-

Headwear: A common challenge with traditional embroidery is the difficulty of stitching onto curved or stiff surfaces. With 3D UV stickers, you can easily add intricate designs to the brim of a cap or a custom patch to clothing, without the hassle of sewing.

-

Footwear: Personalized designs or branding can be applied to shoe tongues, sides, and other hard-to-reach places where embroidery is typically not feasible.

-

Bags: From casual totes to heavy-duty backpacks, 3D UV stickers provide a durable, high-quality focal point on bags of all materials.

Home Décor

-

Soft Furnishings: Elevate your cushion covers and curtains with intricate floral patterns or geometric designs that add texture without the risk of snagging, which often happens with real thread.

-

Linens: Customize tablecloths and napkins with embroidered-style borders for a unique, high-end look in your home decor.

Outdoor and Lifestyle Products

-

Camping Gear: With the waterproof nature of many camping materials, UV embroidery stickers allow branding and personalization without compromising the integrity of the fabric.

-

Pet Supplies: Whether for pet beds, leashes, or backpacks, 3D UV stickers are durable enough to withstand the wear and tear from active pets.

Cultural Products and Souvenirs

-

Souvenirs: Museums and cultural sites can use these stickers to create intricate designs that replicate famous art, providing a more tactile souvenir option than flat printing techniques.

How to Create 3D UV Embroidery Stickers?

Creating 3D UV embroidery stickers is a straightforward process that blends traditional design skills with modern printing technology.

-

Design: Start by creating a high-resolution image file on your computer, typically in PNG or TIFF format. Unlike traditional embroidery, you don't need to worry about the specific stitching patterns, making the design process faster and more flexible.

-

Printing: The design is then sent to a UV printer, which prints the artwork on a special adhesive backing. The UV curing process hardens the ink into layers, creating the desired 3D effect.

-

Cutting: Once printed, the stickers are cut using a precision cutting machine, ensuring that each design is properly shaped and sized for the application.

-

Application: To apply the sticker, simply peel off the backing and press it onto your desired surface. A heat press may be used to ensure a permanent bond.

Why Choose 3D UV Embroidery Stickers?

Here are the top reasons why 3D UV embroidery stickers are quickly becoming the preferred choice for both businesses and creators.

1. Cost-Effective for Small Batches

Traditional embroidery often requires high setup costs, especially when dealing with small orders. 3D UV embroidery stickers eliminate the need for large production runs or complex machinery, making them ideal for small batches or even one-off customizations. Whether you're creating a few pieces of branded merchandise or personalized gifts, 3D UV stickers are a cost-effective option.

2. High Efficiency and Quick Turnaround

Unlike traditional embroidery, which can take a significant amount of time to complete, 3D UV printing is fast. A UV printer can produce multiple stickers in minutes, reducing lead time and enabling quicker fulfillment for businesses. This is particularly useful for time-sensitive orders and short-run custom projects.

3. Unlimited Design Potential

3D UV embroidery stickers offer unparalleled design flexibility. They can handle complex gradients, fine details, and even tiny text with ease, something that traditional thread embroidery struggles to achieve. This opens up endless creative possibilities for designs that go beyond the limitations of needle and thread.

4. Durability and Longevity

The UV curing process creates a tough, long-lasting finish. These stickers are highly resistant to fading, scratching, and wear, making them ideal for items that will see heavy use, like sportswear, pet products, and outdoor gear.

Exploring a New Texture: The Future of Customization

The world of customization is constantly evolving, and 3D UV embroidery stickers represent a breakthrough in the way we think about branding and personalization. Offering a tactile, textured look similar to traditional embroidery, but with the speed and versatility of digital printing, these stickers are opening up new possibilities for small businesses and DIY enthusiasts alike.

With 3D UV stickers, you can create high-quality, professional-looking designs in a fraction of the time, at a lower cost, and with far more creative freedom than ever before.

Conclusion

3D UV embroidery stickers are revolutionizing the world of customization. They offer the premium look and feel of traditional embroidery, with the speed, cost-efficiency, and flexibility that modern businesses require. Whether you’re designing branded products, gifts, or personalized fashion, this technology opens up a new world of possibilities. Embrace the future of printing with 3D UV embroidery stickers, and take your products to the next level.