Sublimation Printing T-Shirts: A Beginner-Friendly Guide!

The Sublimation printing process might seem difficult to some people at first, especially if you’re new to apparel customization. But once you go through the steps, most people are surprised by how doable it is. In fact, many small business owners, home crafters, and even people making shirts just for fun end up sticking with sublimation.

What really sets sublimation apart is how the ink becomes part of the fabric; it doesn’t sit on top the way vinyl does. That’s why sublimation shirts feel smooth when touching, are easy to wash, and keep their bright colors for longer than other prints.

In a simple, beginner-friendly way, we’ll go over what sublimation actually is, what tools you need, the step-by-step process, and many useful tips.

Understanding Sublimation Printing

Although sublimation sounds like a chemistry-related concept, the idea behind it is straightforward. When sublimation ink is heated, it turns into a gas instead of a liquid. When the shirt cools, the ink becomes a solid again, but this time, in the form of the print you did. This is why you can't feel a sublimation print on a shirt.

If you rub your hand over a sublimated design, it feels exactly like the shirt. It also explains why the colors stay so bright even after several washes. The print isn’t sitting on the outside of the shirt, so it can’t peel or crack.

For optimal results, opt for shirts with a high polyester content. A 100% polyester shirt gives you bold, crisp prints. A blend with around 65% polyester still works, just with slightly softer colors. When it comes to colors, lighter shades like white work best because sublimation ink is transparent.

Materials Needed for Sublimation Printing

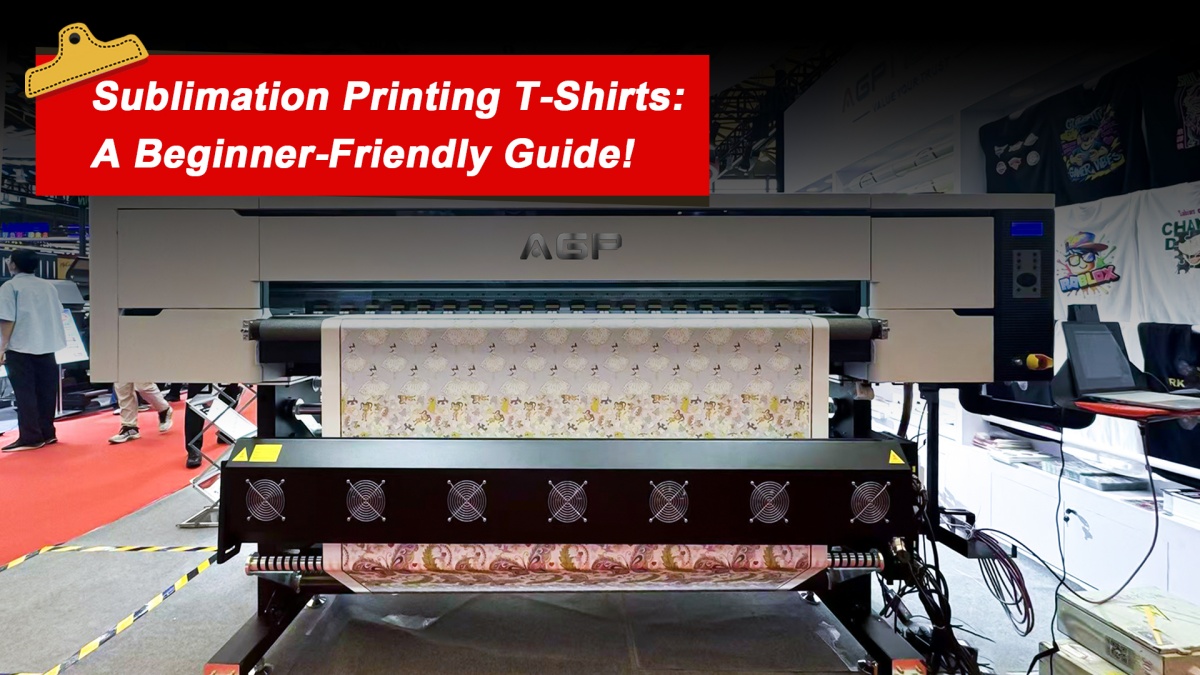

Dye-sublimation printing does not need a big setup, just a printer, inks, films, and a press machine. Make sure you get your supplies and equipment from trusted vendors:

Sublimation Printer and Ink

Use a sublimation printer and ink made especially for sublimation. If you try to use regular ink, the transfer will not happen and you’ll waste your shirts.

Sublimation Paper

Good quality sublimation paper helps you avoid color runs and keeps the details in the print.

Heat Press Machine

A heat press transfers the ink into the polyester fibers from the transfer sheet. You need consistent heat and pressure for the print to come out clear. An iron doesn’t get hot enough and isn’t even, so a heat press is a must.

Blank T-Shirts

Choose polyester shirts; white or light-colored ones give you the brightest results. If you’re experimenting or learning, grab a few cheap blanks first so you don’t stress about mistakes.

Heat-Resistant Tape

This tape keeps your sublimation paper from slipping while the press is closed. Even a little huffle shuffle can cause the print to go bad.

Printing Process: Step-by-Step Guide

Once you get an understanding of the process, sublimation becomes easy and exciting.

Prepare the Design

Open your software and adjust the fit to your shirt. Many designs need to be mirrored so they transfer correctly. This is a tiny detail, but easy to forget when you’re new.

Print on Sublimation Paper

Print your design. Let it dry for a moment; ink transfers better when the paper isn’t smudged or damp.

Place the Shirt on the Heat Press

Lay your shirt flat on the press. Smooth out wrinkles, lint, or folds, because anything between the shirt and paper can cause uneven spots.

Position the Printed Paper

Place the printed side of the sublimation paper exactly where you want the design. Use tape to keep it in place so it doesn’t slide at all.

Apply Heat

Close the lid and apply heat for the recommended time. Sublimation is high heat, usually around 380-400 °F, depending on the fabric and ink.

Remove Paper

Lift the press, peel the paper away slowly, and check your print. Don’t touch the shirt too quickly; let it cool so the fibers settle and the image stays crisp.

Advantages of Sublimation Printing

Bright and Long Lasting Colors

Sublimation prints stay bright even after washing many times because the ink gets into the fabric.

Soft and Smooth Finish

No thickness or texture, just soft, natural-feeling fabric. Good for detailed Designs because sublimation captures detail really well.

No Cracking or Peeling

Because nothing sits on the surface, cracks and peeling just don’t happen.

Fast for Small Batches

You can print a single shirt or a few dozen without needing elaborate equipment or setup time.

Tips for Better Sublimation Results

A few small practices can make your prints look noticeably better:

- Use high-polyester shirts when possible; more polyester means brighter prints.

- Before you print, press the shirt for 5 seconds to remove moisture and wrinkles, and keep your workspace dry. Humidity can mess with ink transfer.

- Double-check the press temperature and time before each run.

- Allow finished shirts to cool completely before folding or packaging them.

Conclusion

Sublimation printing T-shirts is one of those things that looks difficult but is actually really fun once you try it. It is reliable, looks professional, and the prints last way longer than most. Whether you’re making shirts for a business, an event, or just because you want something unique, sublimation gives you a clean, colorful, long-lasting design with very little learning curve.

With the right materials and a bit of practice, you’ll be able to produce bright, smooth prints every time. And honestly, it’s pretty cool to see it come out of the press.