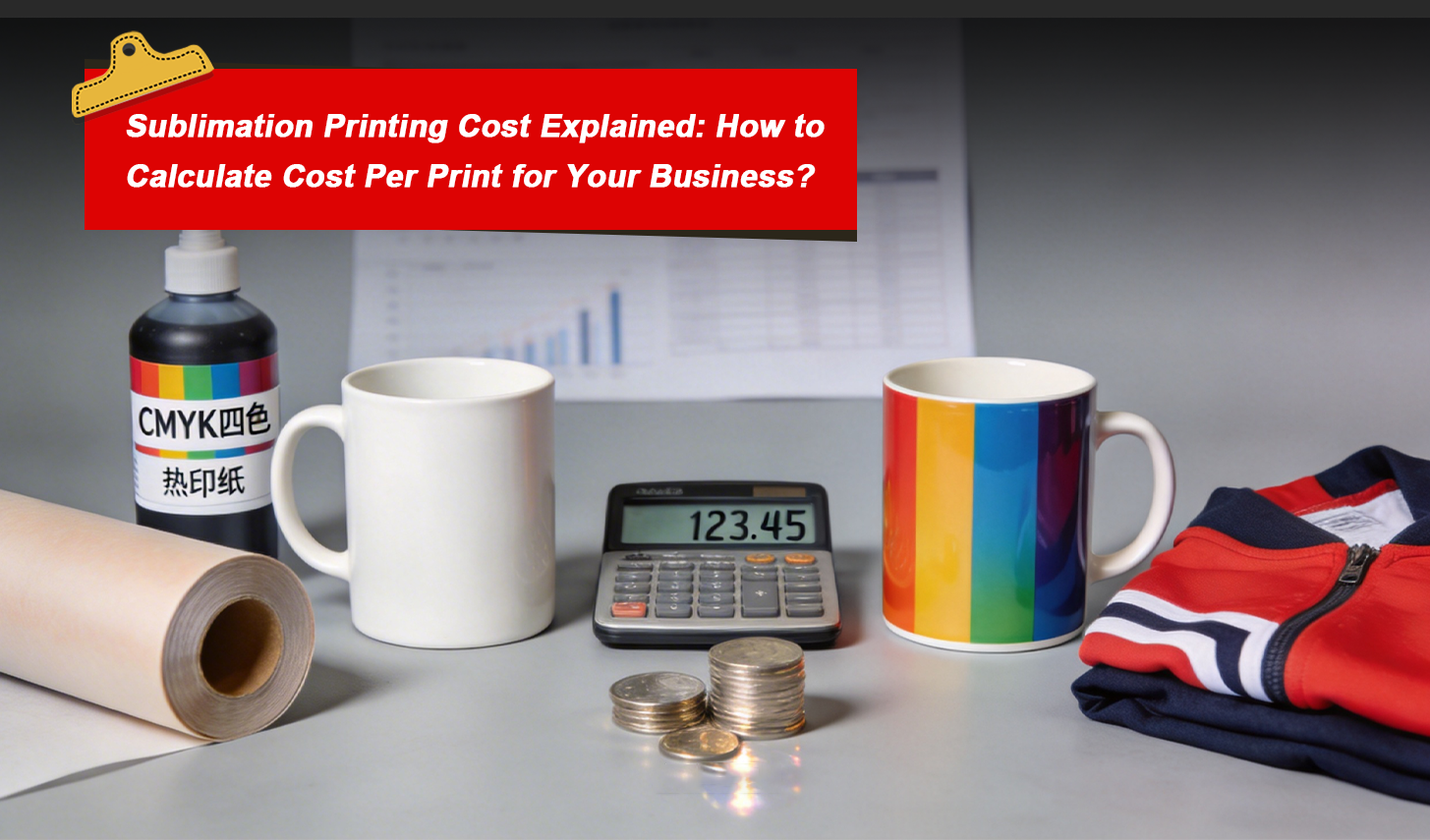

Sublimation Printing Cost Explained: How to Calculate Cost Per Print for Your Business?

Sublimation printing has become one of the most reliable production technologies in the customized printing market. From polyester apparel and sportswear to mugs, photo panels, aluminum sheets and coated hard substrates, sublimation printing offers unmatched color vibrancy, smooth gradients and long-term durability.

However, many beginners and even experienced print shop owners still struggle with one very practical question:

How much does sublimation printing actually cost?

The real challenge is not whether sublimation printing is expensive, but whether you understand how to calculate the true sublimation printing cost accurately — and use that data to build a profitable pricing strategy.

In this guide, AGP will walk you through a complete, professional and easy-to-apply cost structure for sublimation printing businesses, helping you calculate your cost per print and make smarter production decisions.

What Is Sublimation Printing and Why Cost Control Matters

Sublimation printing is a digital heat-transfer printing process in which sublimation ink is first printed onto sublimation transfer paper using a sublimation printer. The printed image is then transferred onto a coated or polyester-based substrate through a heat press machine.

Under high temperature and pressure, the ink sublimates directly into gas and bonds permanently with the coating or polyester fibers.

This is why sublimation printing is widely used in:

-

garment printing business

-

sportswear production

-

personalized gifts and promotional products

-

ceramic and metal photo printing

-

customized home décor

From a business perspective, sublimation printing stands out for its:

-

high image consistency

-

low material waste

-

scalable production workflow

-

suitability for both small batch and bulk production

But without a clear understanding of sublimation printing cost, many print shops underestimate expenses and overestimate profit margins.

That is where structured cost calculation becomes essential.

What Makes Up the Real Cost of Sublimation Printing

In professional manufacturing accounting, the total sublimation printing cost is usually composed of four main parts:

-

equipment cost

-

consumables cost

-

labor cost

-

operational and overhead cost

For a stable sublimation printing business model, every single print should carry its share of these expenses.

Understanding this structure is the foundation for building a sustainable customized printing operation.

Equipment Cost in a Sublimation Printing Business

The first major investment in sublimation printing is equipment.

The two essential machines are:

-

sublimation printer

-

heat press machine

Sublimation printer investment

A sublimation printer is specifically designed to work with sublimation ink and sublimation transfer media.

The price range depends heavily on:

-

print width

-

print speed

-

resolution

-

production capacity

-

intended application

Entry-level desktop sublimation printers for small businesses may cost only several hundred dollars, while industrial sublimation printers for apparel factories and large production centers may reach several thousand dollars.

If you operate a small sublimation printing business focusing on personalized products, low-volume orders and online customization, your printer investment remains relatively controlled.

If your target market is mass customization, sportswear manufacturing or commercial production, higher-performance sublimation printers become necessary.

Heat press machine investment

The heat press machine plays an equally important role.

Common heat press machines include:

-

flat heat press for T-shirts

-

mug press machines

-

rotary heat press machines

-

large-format calendar heat presses

Small flat heat presses typically start around USD 100–300, while professional rotary heat presses for textile production may exceed USD 2,000.

From a cost control perspective, your equipment selection should always match your real production demand and product categories.

Consumables Cost: Ink, Paper and Substrates

Consumables form the most visible and directly measurable part of sublimation printing cost.

Sublimation ink cost

Sublimation ink is specially formulated for sublimation printers and heat transfer applications.

High-quality sublimation ink provides:

-

stable color reproduction

-

fast sublimation reaction

-

reduced head clogging risk

-

strong wash and fade resistance

Although sublimation ink is generally regarded as eco-friendly and non-toxic, its pricing varies significantly between brands and printer platforms.

To calculate ink cost per print, you should focus on:

-

cartridge or bottle price

-

total printable area

-

average ink consumption per design

This allows you to calculate the real sublimation ink cost per job.

Sublimation paper cost

Sublimation transfer paper directly affects:

-

ink release efficiency

-

image sharpness

-

color transfer accuracy

Depending on quality and coating formulation, sublimation paper usually ranges from USD 0.20 to USD 1.00 per sheet.

Professional sublimation printing operations typically choose paper that balances:

-

transfer rate

-

drying performance

-

production stability

Substrate cost

Substrate cost depends on the final product type:

-

polyester T-shirts

-

ceramic mugs

-

aluminum photo panels

-

coated phone cases

-

metal plates

For example:

-

polyester T-shirts usually range from USD 3 to USD 5

-

ceramic mugs usually range from USD 1 to USD 4

Substrate cost is often the largest single consumable expense in sublimation printing production.

Labor and Production Workflow Cost

Labor cost is often underestimated in small sublimation printing businesses.

A typical sublimation printing workflow includes:

-

graphic design and file preparation

-

sublimation paper printing

-

heat transfer operation

-

finishing, inspection and packaging

Design time can vary greatly depending on:

-

customization complexity

-

number of design revisions

-

client approval cycles

Printing and heat pressing are relatively standardized steps, but still require trained operators to maintain consistency and avoid production errors.

Even for owner-operated businesses, your own production time represents a real operational cost that must be included in pricing models.

Energy, Maintenance and Overhead Expenses

Electricity consumption

Both sublimation printers and heat press machines consume electricity.

For example, a sublimation printer using 100 watts operating for one hour consumes 0.1 kWh.

If your local electricity rate is USD 0.12 per kWh, the cost per hour becomes USD 0.012.

Although this seems small per job, electricity cost accumulates significantly over monthly production volume.

Equipment maintenance

Maintenance includes:

-

periodic cleaning

-

replacement parts

-

preventive servicing

For professional sublimation printing equipment, it is reasonable to allocate an annual maintenance budget and distribute it across projected production output.

Overhead costs

Overhead costs include:

-

workshop rent

-

utilities

-

insurance

-

management and administrative expenses

Even if sublimation printing occupies only part of your business operations, a proportional allocation should be included.

How to Calculate Sublimation Printing Cost per Print

A practical and repeatable cost calculation formula can be summarized as:

Total sublimation printing cost per print = consumables cost + labor cost + operational cost + equipment depreciation

Step 1: Calculate consumables cost per print

Ink cost per print:

Divide total ink cost by the total number of printable outputs.

Sublimation paper cost per print:

Divide paper pack price by total number of sheets.

Substrate cost per print:

Direct purchase price of blank product.

Example:

-

Ink set cost: USD 100

-

Total output: 200 prints

Ink cost per print = USD 0.50 -

Sublimation paper: USD 30 for 100 sheets

Paper cost per print = USD 0.30 -

Polyester T-shirt substrate: USD 5

Total consumables cost per print = 0.50 + 0.30 + 5 = USD 5.80

Step 2: Calculate operational and labor cost per print

Example:

-

Annual maintenance cost: USD 200

-

Annual output: 1,000 prints

Maintenance cost per print = USD 0.20 -

Electricity cost per print: USD 0.20

-

Labor cost:

Hourly wage USD 15

Production time 0.1 hour per print

Labor cost per print = USD 1.50

Total operational cost per print:

0.20 + 0.20 + 1.50 = USD 1.90

Step 3: Final sublimation printing cost per print

Total cost per print = USD 5.80 + USD 1.90 = USD 7.70

This number represents your real manufacturing cost before profit margin, marketing cost and platform commissions.

How to Reduce Sublimation Printing Cost Without Sacrificing Quality

Cost control in sublimation printing is not about using cheaper materials blindly.

Professional print businesses focus on:

-

optimizing ink consumption through color management

-

reducing waste during test prints

-

selecting stable sublimation printer platforms

-

improving workflow efficiency

-

minimizing rework caused by transfer errors

Stable hardware and consumables compatibility often reduce hidden costs such as:

-

head clogging

-

transfer failures

-

inconsistent output

-

downtime losses

This is why many professional users prefer working with reliable digital printing equipment manufacturers such as AGP.

AGP provides professional sublimation printing solutions, covering:

-

Sublimation printers for apparel printing

-

Sublimation printers for promotional products

-

heat transfer workflow optimization

-

production consulting support

Conclusion

Sublimation printing does not have a single fixed cost.

The true sublimation printing cost depends on:

-

equipment configuration

-

consumables selection

-

production workflow

-

labor structure

-

operational environment

By systematically calculating equipment depreciation, sublimation ink usage, sublimation paper consumption, substrate cost, labor time and overhead expenses, you can accurately determine your cost per print and build a sustainable pricing strategy.

For print businesses that aim to grow steadily in the customized printing market, mastering sublimation printing cost calculation is not optional — it is a core management skill.

If you still have questions about sublimation printing equipment selection or cost optimization strategies, you can contact AGP for professional consultation and customized sublimation printing solutions.