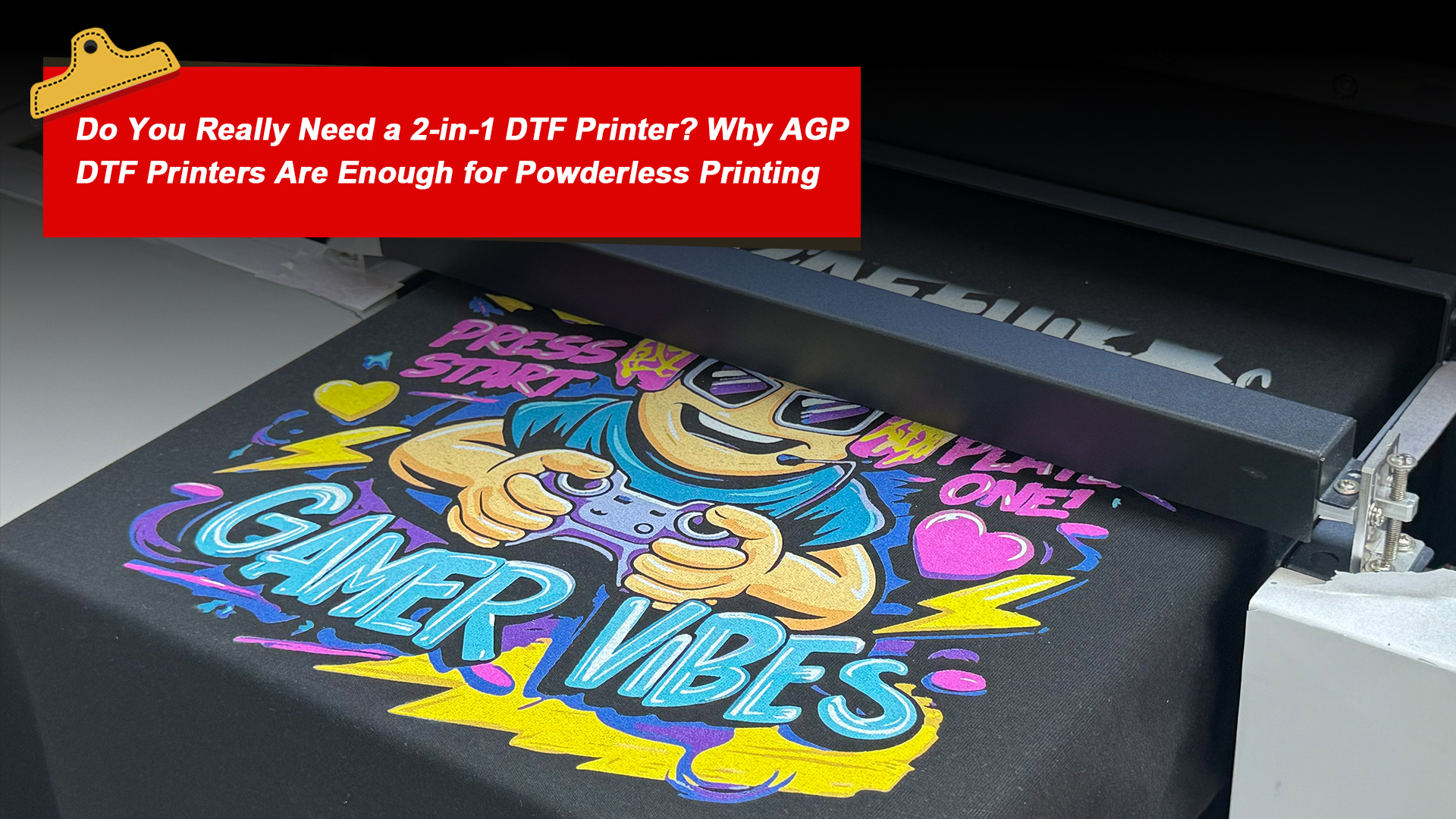

Do You Really Need a 2-in-1 DTF Printer? Why AGP DTF Printers Are Enough for Powderless Printing

The DTF printing industry (Direct to Film) continues to innovate rapidly, reshaping how businesses handle digital textile printing and custom t-shirt production. While many manufacturers now promote 2-in-1 DTF printers that combine powder shaking and powderless printing, the truth is—you don’t need a specialized dual machine to enjoy powder-free printing.

At AGP, our advanced DTF printer series already supports powderless DTF printing solutions using standard hardware with optimized film and ink systems. This provides businesses with the same clean, efficient workflow—without the extra cost or complexity of a combined unit.

What Is Powderless DTF Printing?

Powderless DTF printing is a next-generation process that removes the need for DTF hot melt powder entirely. Instead, a specialized DTF PET film and adhesive ink formula bond directly to fabric when heat-pressed.

This method offers several major advantages:

-

Cleaner workspace — no powder residue or dust.

-

Faster workflow — skip the powder application and curing steps.

-

Environmentally friendly — less waste, fewer emissions.

-

Softer hand feel — prints remain flexible and comfortable on the fabric.

That’s why powderless DTF printing has quickly become one of the most discussed trends in the digital garment printing industry.

Can Regular DTF Printers Print Without Powder?

Yes — and this is where AGP DTF printers stand out.

Although we don’t produce a 2-in-1 powder + powderless DTF printer, our current lineup of DTF printing machines can easily adapt to powderless printing by pairing with the correct powderless DTF film and adhesive ink system.

In practical use, AGP printers deliver:

-

Consistent ink output and strong film adhesion.

-

High-definition DTF transfers for cotton, polyester, denim, and blended fabrics.

-

Compatibility with both powder shaking DTF film and powderless DTF film—giving print shops total flexibility.

This approach offers all the performance benefits of a “2-in-1 DTF printer” while keeping your setup simple, affordable, and scalable.

How AGP DTF Printers Handle Both Printing Methods

1. Traditional DTF Printing Mode

-

Print design on DTF PET film using DTF pigment ink.

-

Apply DTF hot melt powder automatically or manually.

-

Cure, then transfer with a DTF heat press for durable, vibrant prints.

2. Powderless DTF Printing Mode

-

Print directly onto powderless PET film using special adhesive ink.

-

Heat-cure the film surface.

-

Transfer onto fabric via heat press machine—no powder, no residue.

With this flexibility, AGP printers serve both production methods in one system—without needing a hybrid printer.

Why Choose AGP DTF Printers for Powderless Printing?

Versatile Compatibility

Works with both traditional DTF transfer film and new powderless film technology, allowing a smooth transition between workflows.

High-Quality Output

Produces bright, detailed prints with long-lasting colorfastness and resistance to cracking or peeling.

Efficient Production

Eliminates pre-treatment steps and powder handling, enabling faster turnaround for custom apparel printing or on-demand t-shirt orders.

Eco-Friendly Operation

Uses water-based DTF ink and minimizes waste—an ideal choice for sustainable printing businesses.

Reliable Performance

AGP printers include advanced heating and curing systems, automatic maintenance, and stable ink delivery for continuous operation.

Comparing 2-in-1 DTF Printers vs. Standard AGP DTF Printers

| Feature | 2-in-1 DTF Printer | AGP DTF Printer |

|---|---|---|

| Printing Modes | Powder + Powderless | Powderless-capable |

| Complexity | Higher (dual system) | Lower (simpler workflow) |

| Cost | Higher | More cost-effective |

| Maintenance | More parts to maintain | Easy and stable |

| Flexibility | Limited by fixed setup | Works with any DTF film type |

| Output Quality | Excellent | Equal or better (depending on film) |

Applications of AGP DTF Printers

-

Custom t-shirt printing

-

Hoodies, sportswear, uniforms

-

Promotional products & logos

-

Bags, hats, and accessories

-

Home textile printing (cushions, curtains, etc.)

Whether for startups or professional print shops, AGP’s DTF solutions deliver dependable results across a wide range of fabrics and applications.

Conclusion

The future of DTF printing technology is flexible, eco-friendly, and cost-effective—and powderless DTF printing is leading that change. With AGP’s powerful DTF printers, you can achieve powder-free transfers and high-quality results without investing in a complex 2-in-1 DTF machine.

AGP offers a complete, scalable DTF printing solution that supports both powder and powderless workflows—helping your business stay competitive in the fast-growing digital textile printing market.