Spot UV Printing: What It Is and Why It Is Worth It?

Have you ever been handed a business card or product box that appeared somewhat ordinary until it hit the light, and suddenly a portion of it glimmered? That is most likely Spot UV printing.

Spot UV is one of those little finishing touches that cause people to stop and say, “Wait, what’s that?” It’s not in your face, but it adds a certain amount of polish, texture, and professionalism that distinguishes your prints. We’ll discuss what Spot UV printing really is, how it works, when you should use it, and why it may be your new favorite print feature.

Let’s do this.

What is Spot UV Printing?

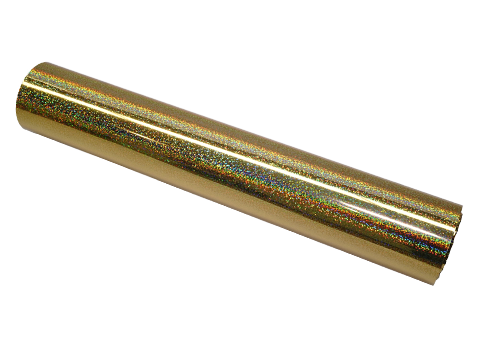

Spot UV printing, which also stands for “ultraviolet” printing, is a process in which a shiny, clear coating is applied to portions of a print design. It’s as if you want to sleek and varnish something to help it pop out. This is very effective as there is a matte flat surface with glossy raised details.

It is referred to as “UV” because the coating is cured or dried by ultraviolet light, which causes it to dry very quickly and adhere well to the paper. Spot UV allows you to highlight a logo, text, or pattern without altering the color option, only adding a glossy and embossed finish.

Spot UV, unlike full gloss coatings, which coat the entire surface, is a more selective and therefore intentional application and that’s the point.

When to Use Spot UV Printing

Spot UV is not for everything, but when used appropriately, it can take your printed piece to another level. And here’s when it really works:

- Business Cards: If you want people to really look at your card, add Spot UV to your logo or name to give it some texture and style.

- Packaging: Use Spot UV on product boxes to highlight branding, patterns, or key features. It gives the packaging a high-end feel without needing foil or embossing.

- Book Covers: Add it to titles or artwork to make them stand out in the light.

- Brochures and Invitations: Great for drawing attention to headings or design elements without overpowering the overall layout.

In short, Spot UV is most appropriate for projects that you wish to add a touch of luxury to without being ostentatious.

The Spot UV Printing Process

Spot UV may sound high-tech, but the process involved is fairly simple:

1. Design Setup

In your design file, make two layers: one for the regular artwork and the other for the Spot UV layer. In the UV layer, there is an indication of where the gloss coating should be, typically in the form of solid black shapes or contours.

2. Printing the Base

The standard inked image is printed first, often using a matte or satin finish so that the glossy portions appear more dramatic.

3. Applying the UV Coating

The UV gloss is printed on top of the spots specified in the file. It's a clear liquid that is applied wet.

4. UV Curing

The coated paper is UV-treated, which immediately dries and fixes the gloss.

Benefits of Spot UV Printing

There’s a reason Spot UV is popular for premium print jobs. Here are some decent benefits:

- Visually Striking: The contrast between matte and glossy finishes instantly grabs attention.

- Professional Feel: It makes business cards, brochures, and packaging look polished and well-thought-out.

- Customizable: You control exactly where the gloss goes: logos, patterns, text, borders, or even subtle background designs.

- No Extra Color: You get extra visual appeal without using more ink or complex graphics.

- Affordable Luxury: It gives a high-end feel without the price tag of foil stamping or embossing.

Things to Consider Before Choosing Spot UV

While Spot UV is a beautiful finishing option, there are some considerations to think about:

- Paper Type is Important: Spot UV works best with coated or smooth papers. Uncoated paper and similar media won’t have the gloss.

- Simplicity in Design: More is Less. When everything is glossy, nothing is. Spot UV should be used with restraint to accentuate and not dominate.

- Cost & Time: It costs a little more and takes a little longer than regular printing, so make sure it’s in your budget and timeline.

- Color Matching: Spot UV does not use ink, so it is important that your design colors work well with the colors underneath, as it cannot repair or enhance the colors of a dull print.

Spot UV vs Other Finishes: What Makes It Different?

Spot UV is different than other finishes in the following ways:

- Full UV Coating: Spot UV is only applied to required areas, whereas full UV coating is applied to the whole surface. This selectiveness is what makes Spot UV so powerful.

- Foil Stamping: It suits better for a metallic look, but it costs more too. Spot UV is just as elegant, but at a more affordable rate.

- Debossing: Debossing pushes the paper down; Spot UV adds texture through the gloss.

Conclusion

Spot UV printing is one of those little touches that can transform your print from average to unforgettable. It’s all about intention, deciding specifically where you want to introduce a little shine to direct the viewer’s eye, emphasize something important, or make your brand appear slicker.

If you’re creating chic business cards, sophisticated packaging, or a fabulous invitation, Spot UV allows you to express more, without noise. It is subtle, sharp, and remarkably inexpensive for the bang it puts out. So the next time you are getting something printed and you want the “wow” factor, you will know what to ask for.