Is a DTF printing business profitable? A to Z Guide on Costs, Demand, and Returns

Is a DTF printing business profitable today, and what is it doing on social media? Direct-to-film printing has grown rapidly because it works on many fabrics, requires less setup, and can be used for short runs. It is also a safe entry point for many new print shops.

This article delineates the profitability of a DTF printing business by separating real costs from market demand, pricing logic, and how to increase margins. Readers will also know the potential returns, risks, and growth potential before investing.

Cost Structure of a DTF Printing Business

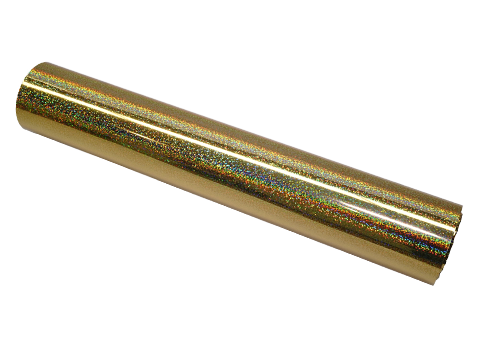

Start-up costs have a direct impact on the potential profit from the very start. A DTF printer, heat press, curing solution, RIP software, inks, films, and powder are some basic setups for DTF. Industrial machines are a bit more expensive than beginner machines, and beginners can start with smaller, entry-level machines.

Operating costs are stable. Costs are ink, film, DTF powder, and electricity. Maintenance is also important, as are print head care and regular cleaning. These costs are easily determined by the use of quality consumables.

Labor adds another layer. In small shops, printing and pressing can be managed by one trained operator. Sometimes, more help is needed as the order volume increases. Rent and utilities are dependent upon location, but many businesses start from home to reduce overhead.

The cost structure is, in general, well-balanced. Scaling can take place incrementally rather than in a single large investment.

Market Demand and Customer Base for DTF Printing

The profitability of a DTF printing business depends on market demand. Online brands, events, and influencer merchandise continue to expand the customization of apparel. DTF is well-suited to this need, which includes cotton, polyester, blends, and even leather.

They serve small businesses, schools, gyms, and startups. They often prefer low minimum orders, timely delivery, and good quality.

DTF is more compatible with these needs than many other approaches.

The seasonal demand also drives sales. Short-term spikes occur during festivals, elections, sports seasons, and corporate events. Shops that plan often turn these periods into months with huge profits.

This also means that revenues vary since DTF supports B2B and B2C orders. This difference allows the client to be less dependent on one type of client.

The Profitability Model of DTF Printing

Profitability is maintained through efficient pricing and efficient workflows. One DTF transfer is relatively cheap. If purchased per print or per garment, margins may remain strong.

Bulk orders multiply hourly profit. The print of gang sheets permits multiple designs on the same film, which reduces material waste. This process generates high output without raising the costs.

Profits also suffer from turnaround time. Faster production equals more orders handled per day. DTF only requires minimal setup, so the short runs will be profitable.

Break-even periods vary, but many small shops start paying initial costs within months of consistent order flow. When equipment is paid off, profits increase again.

DTF vs Other Printing Methods in Terms of Profit

DTF printing is a threat to DTG, screen printing, and sublimation. Both methods are good and bad, but DTF often manages to balance flexibility and cost better.

Screen printing is good for large runs but requires setup time and screens. Small orders are less profitable there. DTG has good details, but has limitations on fabric and ink costs.

DTF, in contrast, does not encounter these challenges because it uses materials that are stable in terms of consumable costs. This limits its market to light polyester products.

DTF tends to have higher average margins for mixed orders and fast turnaround. That balance also partly explains its increasing popularity among new print firms.

How to Turn Your DTF Printing Business into a Profit-Making Machine

Making a DTF printing business profitable all starts with having a solid plan in place & actually sticking to it. But to be honest, that plan is only as good as the person who's implementing it. So quality control needs to come from the top. When you're all clear on what your standards are, and everyone's following them, it just makes things a whole lot smoother all around.

But even with a solid plan in place, you still need to get your pricing strategy right. You can't just charge people based on how much it costs you to do the job; you need to charge based on what that job is actually worth to the person buying it. Things like offering custom designs, rush orders, and printing on tricky fabrics, that kind of thing, all justify a bit of a premium and help keep your profit margins healthy.

And then there's marketing that is a big one for driving in the profits. For a lot of people its social media samples that get the orders coming in, or having some strong local relationships & being able to rely on repeat customers. But it's also worth looking into selling DTF transfers to other printers, which can be a great little side income stream.

Lastly, just getting your workflow sorted is another key part of turning a profit over time. You need to be able to get your design files sorted, batch up your print jobs & streamline your production processes. That saves you both time and materials.

Common Challenges That Affect DTF Printing Profits

Every business faces a hurdle. Paper clogging, film quality, and humidity harm output. Incorrect treatment of these problems is wasteful. Competition has also grown. Newcomers have an increased tendency to underprice services, which increases margins.

This is countered by clear branding and reliable quality. There are learning curves. Mistakes are costly at first, but experience quickly reduces errors. Training and testing prevent long-term loss.

Conclusion

Is a DTF printing firm profitable? Yes, generally, when implemented with realistic expectations and wise decisions. The cost structure is always flexible, market demand is robust, and pricing models have good margins. DTF is good with regard to quality, speed, and fabric range over other approaches.

Efficiency, strong marketing, and consistency in quality enable profit growth. For the businessmen who are looking for an affordable yet modern printing strategy, DTF printing still has some potential in the market.