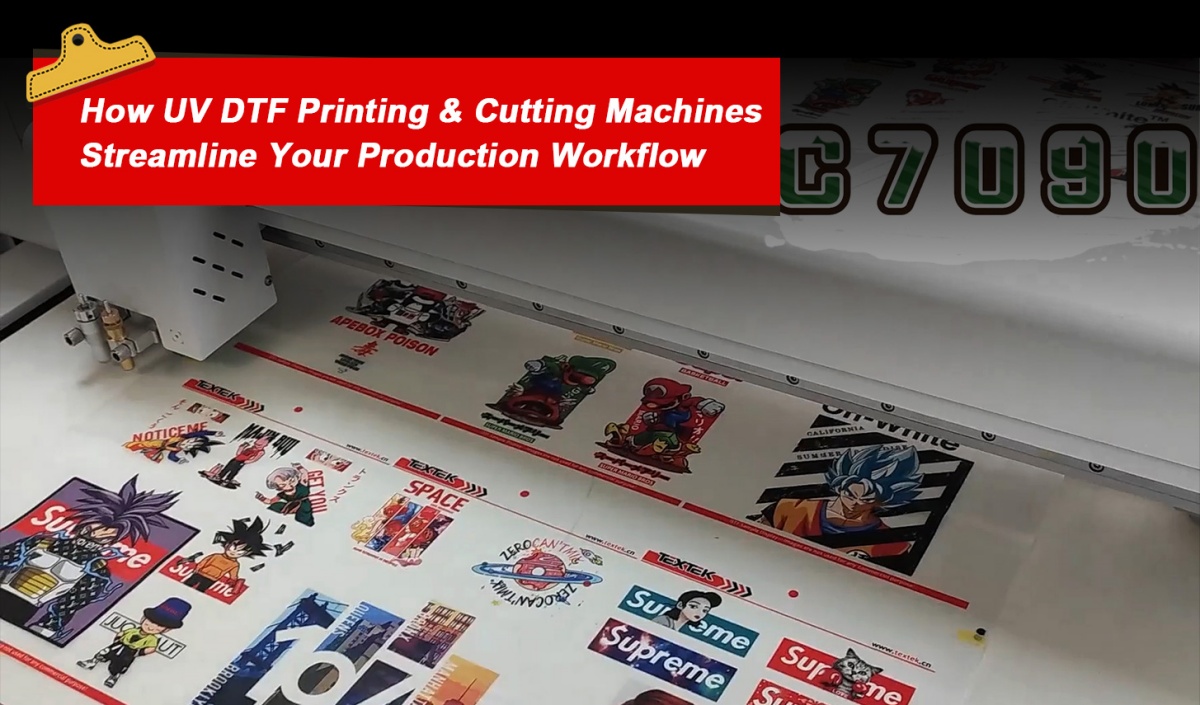

How UV DTF Printing & Cutting Machines Streamline Your Production Workflow

In the competitive world of custom printing, maximizing productivity without sacrificing quality is essential. If your business struggles with slow production, inconsistent cuts, or time-consuming manual processes, integrating a UV DTF printer and a high-precision cutting machine can streamline your workflow and boost profitability. This article explores how combining UV DTF printing with an intelligent cutting system, like the DTF Cutter C7090, can transform your production process, reduce waste, and deliver fast, high-quality custom products.

What is UV DTF Printing?

UV DTF printing is a cutting-edge technology that merges the benefits of both UV printing and DTF printing. Unlike traditional DTF printers that use aqueous inks and powder adhesives, UV DTF printers employ UV-curable inks that are printed directly onto a special film. These inks are cured instantly with UV light, ensuring quick drying and superior durability.

This process creates a long-lasting, waterproof, and scratch-resistant transfer that can be applied to a wide variety of materials, including glass, metal, and plastics. The key advantage of UV DTF printing lies in its versatility—UV DTF transfers can be applied to both soft and hard surfaces with minimal effort, making it perfect for custom merchandise, promotional products, and branding applications.

How Does UV DTF Printing Work?

UV DTF printing involves multiple steps to create a durable, high-quality product. Here's a quick breakdown of how the technology works:

-

Design Creation: Begin by designing your artwork in software such as Adobe Illustrator or CorelDRAW. You’ll need to add registration marks for accurate cutting later.

-

Printing: Once the design is ready, it is printed onto a UV DTF film using the UV DTF printer. The printer lays down the CMYK inks, followed by a white underbase layer and a varnish coating for durability and shine.

-

Curing: The printed inks are instantly cured by UV light, ensuring that the design is vibrant, long-lasting, and resistant to fading.

-

Lamination: The printed film is then laminated to another transfer film (Film B) for protection and ease of application.

-

Cutting: The film is fed into a cutting machine to precisely cut the design from the transfer material.

The Role of UV DTF Cutting Machines in the Workflow

The precision cutting process is crucial to creating clean, professional-looking designs. Unlike traditional cutting methods, UV DTF cutting machines offer automated solutions that save time and enhance accuracy.

Manual cutting or using low-end plotters can result in jagged edges or misalignment. In contrast, a precision cutting machine like the DTF Cutter C7090 integrates seamlessly with UV DTF printers to ensure consistent cuts, perfect for a range of materials, including DTF pet films, self-adhesive vinyl, and crystal labels.

By integrating a cutting machine into the workflow, businesses can achieve faster turnaround times, reduced production errors, and higher-quality products.

DTF Cutter C7090: Key Features and Benefits

The DTF Cutter C7090 is specifically designed for use with UV DTF printers. Below are its key specifications and the benefits it brings to your production line:

-

Max Cutting Speed: 1000mm/s, ensuring fast and efficient cutting.

-

Cutting Thickness: ≤1.2mm, suitable for various materials such as DTF pet film, vinyl, and more.

-

Cutting Pressure: 1000g, allowing for precise cuts without damaging the material.

-

Cutting Methods: Both half cutting and full cutting options for flexibility.

-

Pen/Blade Type: Double-blade structure for improved cutting accuracy.

-

High-Speed Servo Drive: Ensures smooth, consistent motion for precise cutting.

-

Vacuum Suction: Keeps the material secure during cutting to prevent shifting.

-

Compatible Software: Works seamlessly with software like Signmaster, Coreldraw, AI, and AutoCAD.

With a cutting area of 700x900mm and the ability to handle roll-to-roll materials, the DTF Cutter C7090 is ideal for high-volume production of custom merchandise like stickers, labels, and more.

Benefits of an Intelligent UV DTF Workflow

Adopting an intelligent UV DTF workflow can bring numerous benefits to your business. Here's how integrating a UV DTF printer and precision cutting machine can enhance your operations:

1. Enhanced Precision and Quality

By automating the cutting process, precision cutting machines ensure that every design is cut accurately and cleanly. This means no more jagged edges, misalignments, or wasted materials—just professional, high-quality products every time.

2. Versatility in Materials

An intelligent workflow can handle a variety of materials, from UV DTF films to thicker substrates like vinyl and self-adhesive materials. This flexibility allows you to create a broad range of products for different industries.

3. Efficiency and Scalability

Automated workflows increase production efficiency and scalability. By combining UV DTF printing with automated cutting, businesses can fulfill large orders with ease, reducing turnaround times and increasing throughput.

4. Reduced Waste

The combination of accurate cutting and optimized printing ensures that material usage is maximized, reducing waste and cutting costs. By eliminating the need for manual cutting and adjustments, businesses can reduce errors and make better use of expensive materials.

Conclusion: Achieving Seamless, High-Quality Custom Printing

Integrating UV DTF printing with intelligent cutting solutions like the DTF Cutter C7090 creates a seamless workflow that maximizes productivity, reduces waste, and ensures high-quality custom products. Whether you’re creating custom stickers, merchandise, or labels, this advanced printing and cutting technology provides everything your business needs to thrive in the competitive world of custom print products.

Invest in AGP’s UV DTF printing and cutting solutions today and elevate your production process to the next level.