How to Create Custom Phone Cases with UV Printing: A Step-by-Step Guide

As mobile phones continue to be integral to daily life, phone cases have become not only a protective accessory but a fashion statement. With the growing demand for personalized, unique, and high-quality phone cases, businesses and individuals are exploring innovative ways to meet customer needs. This tutorial will walk you through the steps to make customized phone cases using two popular methods: UV Printing and UV DTF Printing.

Step 1: Choosing the Right Material for Phone Cases

Before diving into the customization process, it’s crucial to decide on the material for your phone cases. Different materials offer unique aesthetics and protection, which will influence both the look and durability of the final product. The four most common phone case materials are:

-

Silicone: Known for its flexibility and excellent shock absorption, silicone phone cases offer a soft texture that cushions the phone and provides solid protection against drops. They're a popular choice for those seeking both functionality and comfort.

-

TPU (Thermoplastic Polyurethane): A versatile material offering high wear-resistance, TPU cases are flexible, durable, and resistant to oils, water, and scratches. TPU cases also offer a premium feel and aesthetic appeal.

-

PC (Polycarbonate): A hard material that provides strong protection against impact. Polycarbonate phone cases are less flexible but offer excellent strength, toughness, and durability, making them ideal for users seeking heavy-duty protection.

-

PU (Polyurethane): Combining the lightweight nature of plastic with the flexibility of rubber, PU phone cases provide a comfortable feel while offering decent protection and a sleek, aesthetically pleasing finish.

Choosing the right material is crucial for ensuring the phone case aligns with both functionality and design preferences.

Step 2: Designing Custom Patterns

Once you’ve selected the material for your phone case, it’s time to create the design. This step is key to attracting customers and ensuring your phone cases stand out. Whether you're designing trendy graphics, personalized names, or inspirational quotes, the possibilities are endless.

-

Tip: If you’re struggling for design ideas, AI tools can help generate unique patterns tailored to your preferences. These tools can quickly generate high-quality, customer-specific designs, saving you time and ensuring consistency.

Additionally, offering customization services to your customers allows them to upload their own designs. This approach opens new business opportunities, especially in niche markets where personalization is highly valued.

Step 3: Producing Custom Phone Cases

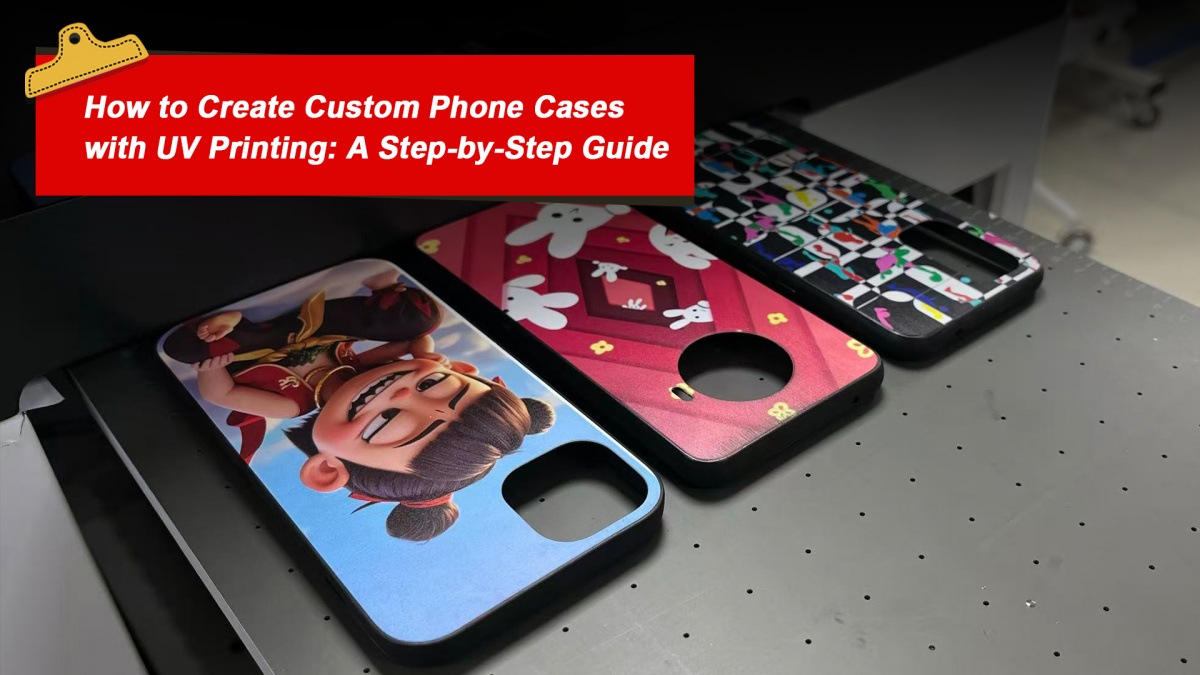

After finalizing your design, it’s time to bring your custom phone cases to life. The two most popular methods for producing high-quality, personalized phone cases are UV Printing and UV DTF Printing.

UV Printing Process

UV printing is an advanced digital printing technology that uses ultraviolet light to cure special inks directly onto the surface of substrates like phone cases. This method ensures vibrant, durable prints that remain intact even with daily use.

-

Advantages: UV printing provides precise, high-resolution prints with rich, full-color detail. It's ideal for printing intricate designs and fine details on any phone case material, whether silicone, TPU, or polycarbonate. The UV-cured ink adheres strongly to the material, ensuring that your design stays vibrant and scratch-resistant.

UV DTF Stickers for Phone Cases

Another excellent method for creating custom phone cases involves UV DTF (Direct-to-Film) printing. This process combines the flexibility of UV printing with the versatility of DTF stickers. Here’s how it works:

-

Step 1: Design the pattern on your computer.

-

Step 2: Use a UV DTF printer to print the design onto a special A-film.

-

Step 3: Apply a B-film to laminate the printed A-film.

-

Step 4: Cut the printed stickers, peel off the A-film, and apply them to the phone case.

-

Step 5: Finally, peel off the B-film to reveal your beautifully printed, high-quality design.

UV DTF printing offers an excellent solution for intricate designs and offers strong adhesion to various phone case materials, ensuring long-lasting, professional results. This method is especially popular for printing complex artwork or vibrant full-color images.

Step 4: Adding Decorative Touches

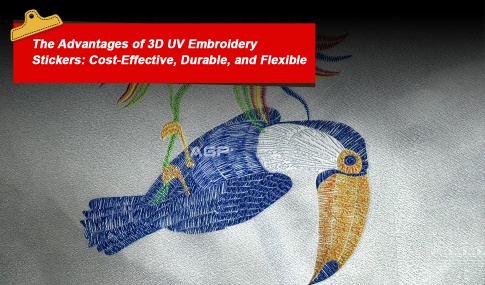

Once the printing is done, you can take your phone cases to the next level by adding decorative elements. This step adds a personalized touch that enhances the visual appeal of the final product.

-

Popular Decorations: Consider adding rhinestones, beads, glitter, or metallic foil to the design for extra sparkle. You can also apply different textures, such as matte, gloss, or embossing, to create more depth and dimension.

-

Custom Embellishments: For a unique touch, include features like engraved logos or personal messages. These small details will differentiate your product and cater to customer preferences for one-of-a-kind designs.

The right decorations will help your phone cases appeal to a wider audience, whether you’re targeting a premium market or creating fun, personalized products for special occasions.

Conclusion: Achieving Stunning Results with UV Printing

UV printing and UV DTF printing offer two powerful methods for creating vibrant, long-lasting, and customizable phone cases. By using UV printers, businesses can produce high-quality designs on various materials, providing customers with personalized products that are durable, beautiful, and unique. The ability to print intricate details and a wide spectrum of colors opens endless possibilities for both personal use and retail.

Whether you’re in the business of custom phone case design or looking to start your own DIY phone case project, UV printing technology is the way forward. With AGP’s advanced printers, you can elevate your product offerings and stay ahead of the competition. Start creating your own line of custom phone cases and bring your designs to life today!

Looking for a UV printer to start your custom phone case business? Contact AGP to explore the best printing solutions tailored to your needs!