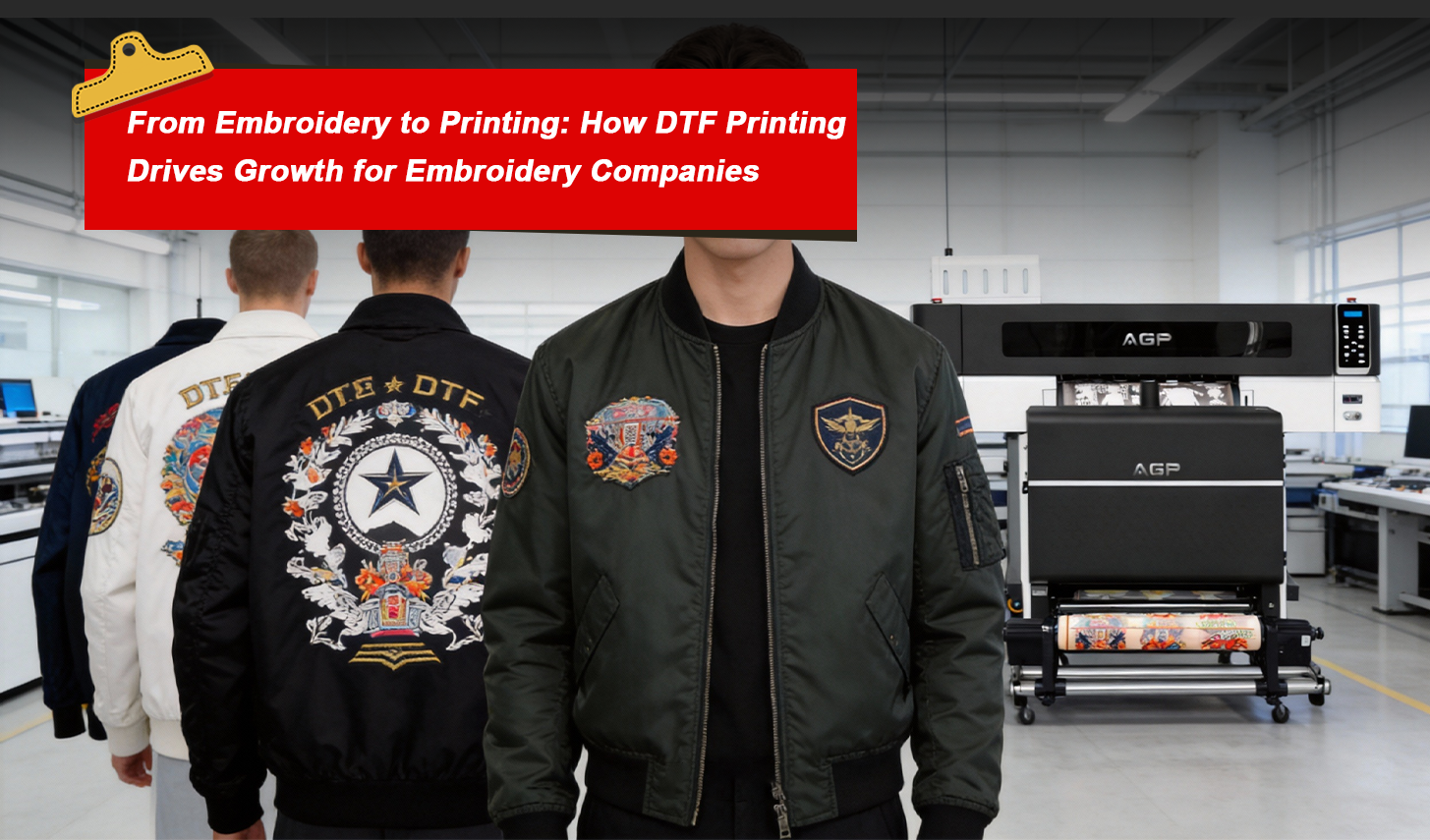

From Embroidery to Printing: How DTF Printing Drives Growth for Embroidery Companies

In today’s highly competitive garment customization market, embroidery businesses are facing a clear challenge: traditional decoration methods alone are no longer enough to meet the growing demand for fast turnaround, full-color designs, small batch customization and creative personalization.

This is exactly where DTF Printing technology becomes a powerful growth engine for embroidery workshops, apparel factories and branding studios.

By introducing a professional DTF printer, embroidery businesses can significantly expand product categories, improve design flexibility and create premium-looking garments by combining digital heat transfer printing with classic stitching craftsmanship.

In this article, we will explore how embroidery and DTF printing solutions can work together, how they differ, and how this hybrid production model can help embroidery businesses build higher profit margins and enter new markets.

What Makes DTF Printing Different from Embroidery

Both DTF Printing and embroidery belong to textile decoration technologies, but their technical logic and production principles are fundamentally different.

DTF Printing, also known as Direct to Film printing, uses a digital inkjet printing process. The design is printed onto a special DTF PET film, coated with hot-melt adhesive powder, cured, and then transferred onto fabric using a heat press.

Embroidery, on the other hand, converts digital artwork into stitch data and physically stitches threads into the fabric through an embroidery machine.

From a business perspective, DTF Printing is a digital production technology, while embroidery is a mechanical textile processing technique.

This difference is exactly why the two methods complement each other extremely well.

Design Capability: DTF Printing vs Embroidery

When it comes to design freedom, DTF Printing technology clearly offers wider creative space.

A professional DTF printer can reproduce:

-

fine gradients

-

photographic images

-

small text

-

complex multi-color artwork

-

unlimited color combinations

DTF Printing is not restricted by color counts or thread limitations. It supports high-resolution graphics and smooth color transitions, making it ideal for:

-

fashion graphics

-

character illustrations

-

sports artwork

-

brand visual systems

-

creative IP merchandise

Embroidery, however, performs better with simple logos, line-based designs and limited color compositions. Complex images often require heavy digitizing, higher stitch density and longer production time.

For embroidery workshops that frequently receive complex design orders, introducing DTF Printing equipment significantly reduces production difficulty and rejection rates.

Production Workflow and Equipment Requirements

Understanding production flow is essential when upgrading an embroidery business.

The standard DTF printing workflow includes:

-

Artwork design and RIP processing

-

Printing on DTF transfer film using a DTF printer

-

Hot-melt powder application

-

Curing process

-

Heat press transfer onto fabric

This workflow can be completed with a DTF printing machine, powder shaker & dryer, and a heat press.

Embroidery production includes:

-

Artwork digitizing

-

Thread color mapping

-

Stitch programming

-

Fabric hooping

-

Stitching process

From a business operation perspective, DTF Printing allows faster job switching, easier staff training and shorter preparation cycles.

This is why many embroidery workshops are now upgrading their production lines with DTF printing systems to handle digital graphic orders efficiently.

Fabric Compatibility and Application Scenarios

One of the strongest advantages of DTF Printing solutions is fabric compatibility.

DTF Printing can be applied on:

-

cotton

-

polyester

-

blends

-

nylon

-

spandex

-

softshell

-

denim

-

dark and light fabrics

This makes DTF Printing extremely suitable for diversified product lines such as:

-

T-shirts

-

hoodies

-

jackets

-

caps

-

tote bags

-

uniforms

-

sportswear

Embroidery performs best on thicker and structurally stable materials, such as:

-

cotton twill

-

fleece

-

denim

-

woven fabrics

By combining DTF printing machines with embroidery equipment, workshops can handle almost all garment categories without limitations.

Touch, Texture and Durability Comparison

DTF Printing creates a flexible and smooth ink layer on the garment surface. The touch feeling is soft, elastic and comfortable when using high-quality DTF inks and transfer films.

However, due to the adhesive layer, DTF prints may feel slightly less breathable on large coverage designs.

Embroidery delivers a naturally textured surface. The thread stitches create a three-dimensional structure, giving garments a premium handcrafted appearance.

In terms of durability:

High-quality DTF heat transfer printing offers:

-

strong wash resistance

-

good stretch performance

-

stable color retention

Embroidery remains one of the most durable decoration methods, since stitches are physically embedded into the fabric structure.

By combining both methods, brands can offer garments that look premium while maintaining excellent wear resistance.

Cost Structure and Profit Model

For small and medium embroidery workshops, cost control is always a core business issue.

DTF Printing offers several economic advantages:

-

no screen making

-

no color separation

-

low setup cost

-

suitable for small batch production

-

suitable for one-piece customization

A compact DTF printer for small business can generate fast ROI by supporting both sample production and commercial orders.

Embroidery involves:

-

digitizing cost

-

thread consumption

-

machine time

-

labor cost

For complex multi-color designs, embroidery production costs rise rapidly.

This is why many embroidery workshops now use DTF Printing for complex graphic areas and reserve embroidery for logos and premium elements.

Why Combining DTF Printing and Embroidery Creates Higher Value Products

The real business breakthrough comes when embroidery workshops integrate DTF Printing technology instead of treating it as a competitor.

DTF Printing provides:

-

rich color layers

-

background graphics

-

visual storytelling

Embroidery provides:

-

texture

-

brand craftsmanship

-

perceived luxury

Together, they create hybrid garments that deliver both visual impact and tactile value.

This combination is increasingly popular in:

-

premium fashion brands

-

sports team apparel

-

streetwear collections

-

corporate uniforms

-

promotional merchandise

The hybrid workflow allows embroidery businesses to reposition themselves from basic service providers to creative garment solution suppliers.

Typical Applications for DTF Printing + Embroidery

Branded Apparel

Corporate uniforms, workwear and promotional clothing benefit greatly from the combination of DTF Printing and embroidery.

For example:

-

company slogan and background graphics printed by DTF printer

-

company emblem embroidered on chest or sleeve

This enhances both branding visibility and professional image.

Fashion and Designer Collections

Designers use DTF Printing to produce full-color patterns and artistic images, while embroidery adds decorative highlights and luxury finishes.

This hybrid technique enables small fashion studios to create limited collections without high production investment.

Event and Sports Merchandise

Event T-shirts, team jerseys and fan merchandise often require colorful graphics and durable identity marks.

DTF Printing handles artwork efficiently, while embroidery reinforces brand elements such as:

-

event logos

-

sponsor marks

-

team badges

Business Benefits of Integrating DTF Printing into Embroidery Workshops

Introducing DTF printing equipment brings multiple strategic advantages:

Expanded Product Portfolio

DTF Printing allows embroidery workshops to accept:

-

photo-quality artwork orders

-

full-color fashion designs

-

personalized customization requests

Higher Perceived Product Value

Hybrid garments command higher selling prices due to:

-

richer design layers

-

visual differentiation

-

craftsmanship impression

Faster Order Turnaround

DTF Printing drastically shortens sampling cycles and short-run production time.

Improved Market Competitiveness

Workshops that combine embroidery and DTF Printing can directly compete with:

-

digital print studios

-

fashion customization brands

-

online print-on-demand platforms

How to Start a Hybrid DTF Printing and Embroidery Production Line

To successfully build a hybrid production workflow, embroidery businesses should focus on three key areas.

Choose Reliable DTF Printing Equipment

Selecting a stable DTF printer manufacturer is critical. Important factors include:

-

printhead stability

-

ink circulation system

-

white ink management

-

film feeding accuracy

-

after-sales support

AGP provides complete DTF printing solutions for apparel decoration businesses, supporting small workshops and industrial production lines.

Standardize Design Workflow

Integrate RIP software and embroidery digitizing systems so designers can plan:

-

which areas use DTF Printing

-

which elements use embroidery

Train Operators

Although DTF Printing is easier to operate than many traditional printing systems, operators must still understand:

-

film handling

-

powder curing

-

heat transfer temperature control

-

artwork color management

Conclusion

DTF Printing is no longer just a trend in garment decoration.

It has become a powerful digital manufacturing tool that helps embroidery businesses break production limitations, expand design capability and increase overall profitability.

By integrating DTF Printing technology into embroidery workshops, companies can:

-

accept more diversified orders

-

reduce production bottlenecks

-

build high-value hybrid products

-

enter premium customization markets

The combination of embroidery craftsmanship and digital DTF heat transfer printing creates garments that are visually powerful, structurally durable and commercially competitive.

For embroidery businesses seeking sustainable growth, adopting DTF Printing is not an optional upgrade—it is a strategic transformation.

If you are planning to introduce professional DTF printer solutions into your embroidery production line, AGP can help you build a stable and scalable digital printing system for long-term business development.