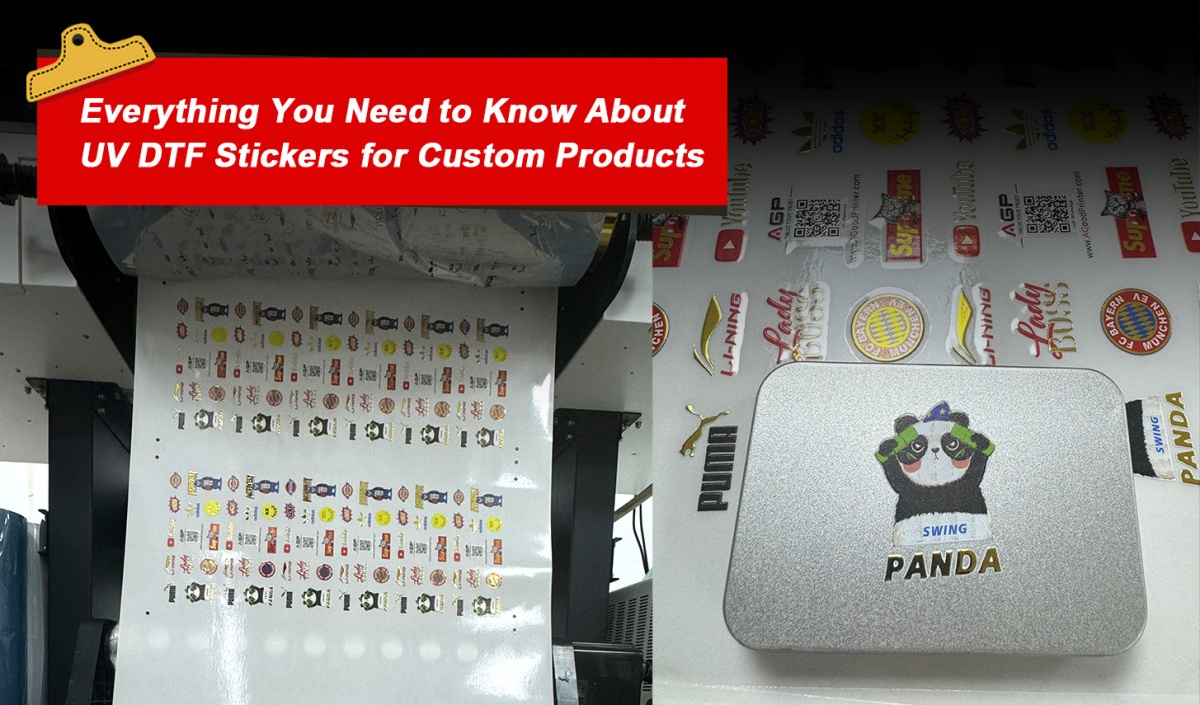

Everything You Need to Know About UV DTF Stickers for Custom Products

In the dynamic world of custom printing, UV DTF stickers are quickly gaining popularity. They combine the best qualities of traditional printing with modern digital technology, offering durable, vibrant, and versatile designs. Whether for promotional materials, custom gifts, or brand packaging, UV DTF stickers provide businesses with the flexibility they need to stand out. Let’s dive into the world of UV DTF stickers and explore why they are revolutionizing the way we think about printing.

What Are UV DTF Stickers?

UV DTF stickers, also known as crystal labels, have become a standout product in the custom printing industry. Unlike traditional labels that are flat and one-dimensional, these stickers have a crystal-like transparency, adding depth and richness to designs. Their unique feature lies in their ability to adhere to a wide range of substrates, including leather, wood, plastic, metal, glass, ceramics, and more.

Using UV DTF printing technology, these stickers provide a high-quality finish that stands out from other types of labels. They create designs that are not only visually appealing but also durable and long-lasting, making them perfect for both indoor and outdoor applications. UV DTF stickers are also known for their three-dimensional texture, which adds an elegant and sophisticated touch to any product.

How Are UV DTF Stickers Made?

The creation of UV DTF stickers involves a simple yet highly effective printing process. Here’s a breakdown of the key steps:

-

Design Creation: The process starts with the creation of a high-resolution design using graphic software such as CorelDRAW or Adobe Illustrator. The design is then prepared for printing, making sure to include registration marks for precise cutting.

-

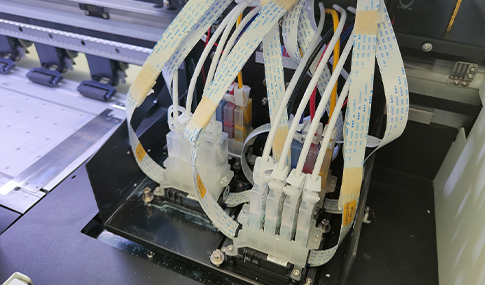

Printing: The design is printed onto a specialized UV DTF A film using a UV DTF printer. This printer applies multiple layers, including the CMYK color layer, a white ink layer for opacity, and a final varnish layer for gloss and durability.

-

Lamination: After the printing is done, the film is laminated with a UV DTF B film to form a protective layer that ensures the sticker’s strength and longevity.

-

Cutting: The laminated film is then passed through a cutting machine, such as the DTF Cutter C7090, where the stickers are precisely cut to shape.

-

Peeling and Application: The final step involves peeling off the B film and applying the sticker to various substrates. The adhesive on the back ensures a strong bond, while the UV ink ensures the colors remain vibrant and resistant to wear and tear.

Benefits of UV DTF Stickers

UV DTF stickers offer several key advantages that make them a popular choice for various industries:

1. Durability

UV DTF stickers are known for their resistance to fading, scratching, and weathering. The UV-curing ink used in the process ensures that the stickers remain intact and vibrant for a long time, even in harsh conditions.

2. Vibrant Colors

One of the main selling points of UV DTF stickers is their vibrant color reproduction. The printing process allows for a wide color gamut, creating designs that are bright and eye-catching.

3. Versatility

These stickers can be applied to a wide range of materials, making them highly versatile. Whether it’s for custom packaging, promotional items, or even personal accessories, UV DTF stickers provide an excellent solution for many applications.

4. No Need for Pre-Treatment

Unlike other printing methods, UV DTF printing doesn’t require pre-treatment of the materials. This makes the process quicker and more cost-effective, especially for businesses that need to produce small or customized batches.

5. Eco-friendly

The UV printing process uses less energy and emits fewer volatile organic compounds (VOCs) compared to traditional printing methods, making it a more environmentally friendly option.

How to Use UV DTF Stickers Correctly

While UV DTF stickers offer numerous benefits, it's important to follow some basic guidelines to ensure their longevity and performance:

1. Material Suitability

Ensure that the surface you're applying the stickers to is hard and smooth. UV DTF stickers adhere best to materials like glass, metal, plastic, and ceramics. Fabrics are generally better suited for traditional DTF printing.

2. Temperature Control

Avoid exposing the stickers to high temperatures or hot water, as this could affect the adhesive quality and visual effects of the stickers.

3. Proper Peeling

When peeling the AB film, ensure that it is done smoothly and at the correct angle. This helps avoid damaging the design and ensures a clean application.

Market Prospects for UV DTF Stickers

The demand for UV DTF stickers has been steadily growing, especially as businesses continue to look for innovative ways to personalize and brand their products. From custom packaging and labels to promotional giveaways, UV DTF stickers are becoming an essential part of branding strategies across industries.

As customer preferences shift towards more personalized and unique products, UV DTF stickers provide businesses with a way to meet these demands without sacrificing quality or efficiency. With the growing trend of e-commerce and online businesses, UV DTF stickers are poised to become even more prevalent in the coming years.

Conclusion

UV DTF stickers are not just a passing trend—they are a game-changer in the world of custom printing. Offering superior quality, vibrant colors, and versatility, they provide businesses with the tools they need to elevate their branding and packaging. Whether you're looking to create personalized gifts, custom merchandise, or eye-catching packaging, UV DTF stickers offer a durable and effective solution.

As the market continues to demand high-quality, customizable products, investing in UV DTF sticker printing is a smart move for any business looking to stay competitive. For businesses seeking advanced printing and cutting solutions, AGP offers top-tier UV DTF printers and cutting machines, ensuring that your production process is as efficient and high-quality as possible.