Everything You Need to Know About DTF Transfers

The global market is getting new technologies on daily basis. When it comes to printing techniques, there are a lot. DTF Transfer is top most printing technique. It is getting popularity among competitors through its accessibility for small businesses. However, why is DTF transfer such a revolutionary concept? Let's read its working, benefits and more.

What is DTF Transfer?

Direct to film transfer is a unique technology. It involves direct printing on a pet film and transferred to the substrate. DTF transfer doesn’t require any other treatment before printing. This makes the DTF transfer stand out. Moreover, DTF transfer can accommodate various substrate types. It includes: cotton, polyester, nylon, silk, denim, and fabric blends.

DTF printing is a best choice among traditional screen printing and digital printing due to its durable designs. Ideally, DTF is selected for detail-oriented projects that need vibrancy of colors regardless of the fabric type.

Think of DTF as a cross between classic screen printing and modern digital printing, providing the best of both worlds. DTF is ideal for projects that demand high detail and brilliant colors independent of the fabric composition.

How DTF Transfer Works

While transforming designs into film may appear complex, the DTF technique is simple. Here's an explanation of how it works:

Design Creation:

Each DTF process begins with a digital design. There are multiple ways to get your digital design. You can use a design tool like illustrator to make yours or import any design that you want to print. All you need to focus on is to ensure the design is reversed. It needs to be flipped on the fabric after printing.

Printing on PET Film:

DTF printing involves special PET film, which is used to take to digital design and paste to your fabric. The film is ideally 0.75mm thick which is ideal for giving compact designs. A unique DTF printer prints the design in CMYK color, with a final layer of white ink applied to the complete image. This ink illuminate the design when applied to the dark materials.

Application of Adhesive Powder:

Once the print is ready to be placed on fabric, hot-melt adhesive powder is added. It works as the bonding agent between the design and the fabric. Without this powder, DTF design cannot be secured. It gives the uniform designs that is placed on the material.

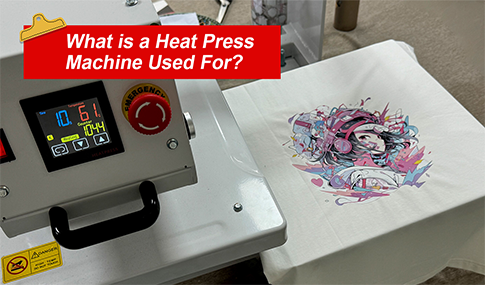

Curing Process:

The curing process is related to securing the adhesive powder. It is performed by using a curing oven specialized for the adhesive powder settings. Furthermore, you can use a heat press at a low temperature to cure it. It melts the powder and let it stick the design with the fabric.

Heat Transfer to Fabric:

Heat transfer is the final stage, the cured film is to be placed on the fabric. Heat press is applied to let the design stick to the fabric. The heat is applied often at 160°C/320°F for around 20 seconds. This heat is enough for the adhesive powder to melt and stick the design. Once the fabric is cooled, PET film is removed gently. It gives the gorgeous design on fabric with amazing colors.

What are the Advantages and Disadvantages of the DTF Transfer?

Despite its all the advantages, DTF transfer comes with some challenges. Its advantages are way more, which makes it stand out. It is considered as an attractive option for printings. Let’s explore them in detail:

Advantages:

- DTF transfer can print on various materials. It can handle cotton, polyester and even textured materials like leather.

- DTF transferscan effectively produce designs with vibrant colors. It never compromise on design quality.

- The CMYK ink used in this technique ensure the pattern is on point and don’t mx dark and light colors.

- As DTG often needs pre-treatment, DTF can be directly applied to the fabric without additional steps. It saves time and much effort.

- Screen printing is suitable for bulk prints, but DTF is highly cost-effective for smaller orders or single pieces. You don’t need to make a vast setup for these designs.

- DTF transfers produce long-lasting prints. The long lasting and durable nature is due to the adhesive powder used in this technique. It makes the design intact even after multiple washes.

Disadvantages:

- Each design has a unique film, material waste is considerable. However, if the process is optimized, then it can be covered. It can also add up for larger projects.

- The placement of adhesive powder is an extra step. It complicate things for newbies.

- While DTF works on a wide range of fabrics, the print quality may be a bit low in flexible materials like spandex.

Comparison with Other Transfer Methods

Let us compare the DTF transfer with other printing methods to better understand their processes

DTF vs. DTG (Direct-to-Garment):

Fabric Compatibility: DTG printing is limited to print on cotton fabrics, whereas DTF can be applied to various substrates. This makes it significantly more versatile.

Durability: DTF prints after several washes remain intact and proved to be highly durable. However, DTG prints fade away quickly.

Cost and Setup: DTG is suitable for detailing and multi-colored designs. However, it requires costly equipment before procedure. DTF don’t need any before treatment. Print are directly made on fabrics through heat press.

DTF vs. Screen Printing:

Detail and Colour Precision: DTF is best at producing detailed, multicolored graphics. In contrast, screen printing struggles to capture fine details.

Fabric Limitations: Screen printing works best on flat, cotton fabrics. DTF offers various fabric types including the textured stuff.

Setup and Cost: Here screen printing needs various distinct screens for different colors. It makes the process slow and costly for small projects. DTF is super convenient to small projects.

Why DTF is a Game Changer for Custom Printing

DTF transfer has got the fame due to its user-friendly methodology. It is equipped with modern technology which never compromise on colors, quality and durability of prints. Furthermore, its inexpensive setup costs equally suit small businesses, amateurs, and large-scale printers.

DTF transfer is expected to become more prevalent as film and adhesive technology improves. The future of bespoke printing is arrived, and DTF is leading the way.

Conclusion

DTF transfer is a modern technique of printing. It is designed to give versatile designs in low cost and high quality. More importantly, you are not bound to print o fabrics only. You can choose from various substrate types. No matter, you are a newbie or a professional, DTF transfer will make your printing experience easier and smart.