Custom DTF Prints: A Complete Guide for Modern Printing Businesses

In today’s highly competitive customization market, brands can no longer rely on ordinary products to win customer attention. Consumers are demanding personalization, durability, and vibrant visual impact—and Custom DTF Prints have quickly become one of the most reliable solutions to meet these expectations.

Direct to Film (DTF) printing has transformed how businesses approach textile decoration. With flexible production, strong color performance, and low entry barriers, custom DTF prints are opening new opportunities for apparel brands, promotional companies, and print-on-demand businesses worldwide. In this article, we’ll explore what custom DTF prints are, why they matter, and how they can help grow your business efficiently.

What Are Custom DTF Prints?

Custom DTF prints refer to personalized designs created using DTF printing technology, where artwork is printed directly onto a special DTF film and later transferred onto fabric using heat and pressure. Unlike traditional printing methods, DTF printing does not limit you to specific fabric types.

DTF prints work seamlessly on cotton, polyester, blends, nylon, denim, leather, canvas, and more. This flexibility makes DTF prints ideal for businesses that want to serve multiple markets without changing equipment.

The process uses DTF printer, DTF ink, hot melt powder, and heat press machines to produce prints with excellent color accuracy, sharp edges, and long-lasting durability. From bold logos to fine text and complex gradients, custom DTF prints deliver consistent results across both light and dark fabrics.

Why Custom DTF Prints Are Reshaping the Printing Business

The rise of custom DTF printing is not accidental. It responds directly to market changes: faster turnaround, smaller batch orders, and higher customization demands.

Compared with screen printing or DTG printing, custom DTF prints remove many traditional limitations. There is no need for plate making, no minimum order quantity, and no complex fabric pretreatment. Businesses can fulfill one-piece orders just as easily as bulk production.

For startups and expanding print shops, DTF prints represent a low-risk, scalable business model. One DTF printer can handle a wide range of products, allowing businesses to test new niches quickly without heavy investment.

Key Advantages of Custom DTF Prints for Growing Brands

1. Outstanding Versatility

Custom DTF prints are not limited to T-shirts. They can be applied to hoodies, jackets, tote bags, caps, shoes, socks, and even home textiles. This versatility allows brands to diversify product lines effortlessly.

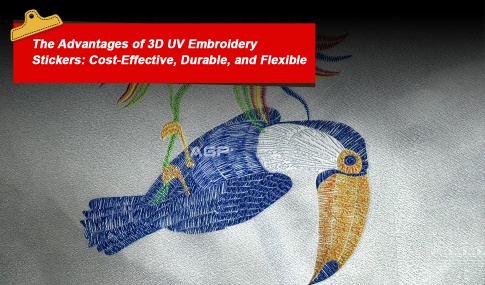

2. Long-Lasting Durability

DTF prints offer excellent wash resistance and stretch performance. Designs remain vibrant after repeated washing, cracking and fading are minimized, making them suitable for daily wear and professional uniforms.

3. High-Level Customization

With DTF printing, businesses can upload customer designs directly and print on demand. Whether it’s a personalized name, limited-edition artwork, or corporate branding, customization becomes simple and efficient.

4. Cost-Effective Production

A single DTF printer setup supports multiple products, reducing equipment costs. Combined with low material waste, DTF printing delivers strong profit margins, especially for small and medium-sized businesses.

5. Precision and Detail

DTF technology excels at fine details. Small text, thin lines, and intricate logos are printed clearly, making it ideal for fashion branding and label printing.

Popular Applications of Custom DTF Prints Across Industries

Apparel and Fashion

The most common application of custom DTF prints is clothing. From casual wear to fashion collections, DTF printing supports vibrant colors and complex designs on T-shirts, sweatshirts, dresses, jeans, and more.

Home and Lifestyle Products

Custom pillow covers, blankets, curtains, and fabric wall décor are increasingly popular. DTF prints allow home brands to offer personalized and seasonal designs with minimal setup.

Promotional Products

DTF prints are widely used for promotional bags, uniforms, and giveaways. Printing logos and slogans helps businesses increase brand visibility while keeping production flexible.

Sportswear and Activewear

Sportswear requires stretchability and durability—both are strengths of DTF prints. Custom team uniforms and fitness apparel are fast-growing applications in the DTF printing market.

How Custom DTF Prints Are Made: Step-by-Step Process

The DTF printing process is straightforward but highly efficient:

Step 1: Design Preparation

Create original designs or receive customer artwork. Use RIP software to convert files into printable formats with correct color profiles.

Step 2: Film Printing

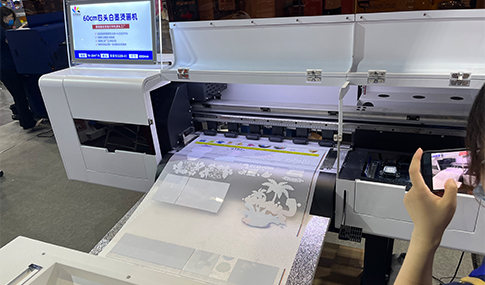

The DTF printer prints the design onto a coated DTF film using CMYK and white ink. Hot melt powder is applied automatically or manually to the wet ink layer.

Step 3: Curing

The powder-coated film is cured using a curing oven or integrated heating system until the adhesive layer is activated.

Step 4: Heat Transfer

Using a heat press machine, the cured design is transferred onto fabric with controlled temperature and pressure.

Step 5: Finishing

After cooling and peeling, the final product is ready for sale with a professional and durable finish.

Equipment and Materials Needed for Custom DTF Prints

To start producing custom DTF prints, the following equipment is essential:

-

DTF Printer

-

DTF Ink (CMYK + White)

-

DTF Film

-

Hot Melt Powder

-

Heat Press Machine

-

RIP Software

-

Powder Shaker

-

Curing Oven

Choosing high-quality equipment and consumables directly affects print quality and long-term stability.

Make or Buy? How to Source Custom DTF Prints Efficiently

Businesses can obtain custom DTF prints in two main ways:

Produce In-House

Purchasing a DTF printer allows full control over quality, turnaround time, and customization. This option is ideal for businesses planning long-term growth.

Outsource to Factories

Buying custom DTF prints from professional manufacturers helps reduce upfront costs. This method works well for testing markets or handling peak orders.

Regardless of the method, requesting samples is crucial to evaluate adhesion, color performance, and durability.

AGP provides reliable DTF printing equipment and consumables, helping businesses achieve stable production and consistent results.

FAQs About Custom DTF Prints

Are custom DTF prints suitable for dark fabrics?

Yes. White ink ensures strong opacity on both light and dark materials.

Do DTF prints crack after washing?

High-quality DTF prints offer excellent wash resistance when applied correctly.

Is DTF printing eco-friendly?

Modern DTF inks are designed to meet environmental standards with low odor and reduced waste.

Conclusion

Custom DTF prints are more than just a printing method—they represent a scalable, flexible, and profitable business opportunity. With wide material compatibility, durable performance, and strong visual impact, DTF printing empowers businesses to meet modern customization demands with confidence.

Whether you plan to start a new printing business or expand existing services, investing in custom DTF prints can help you stand out in a crowded market and build long-term value.

If you are looking for reliable DTF solutions, AGP offers professional DTF printers, inks, films, and technical support to help you succeed.