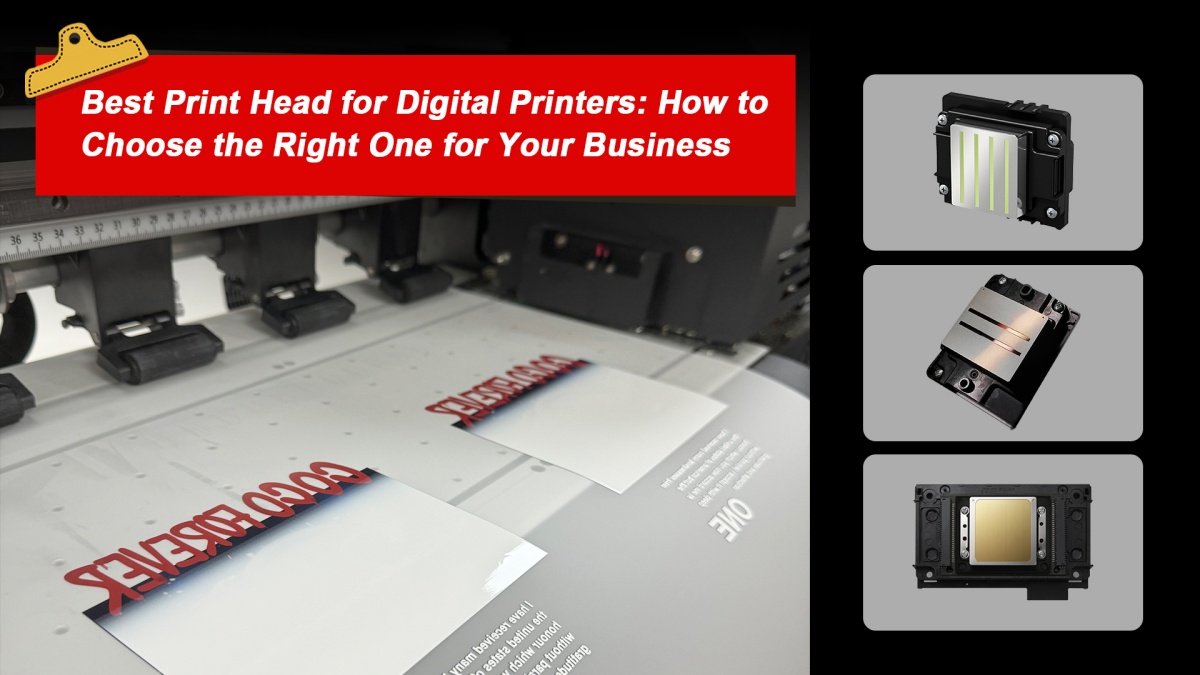

Best Print Head for Digital Printers: How to Choose the Right One for Your Business

In digital printing, everything comes down to the print head. It is the part that controls how sharp your images look and how smoothly your printer runs. Pick the right one, and your prints stay sharp and consistent. Pick the wrong one, and you’ll be fixing clogs and streaks more often than printing.

This article tells you what a print head does, the main types you’ll come across, and how to choose one that is best for your business needs.

Understanding the Role of a Print Head in Digital Printing

The print head is what determines where and how much ink to place, how large the droplets are, and how fast they’re sprayed out. The print head contains many nozzles and electronics; it is the part in a printer that sprays out ink onto the surface of your substrate.

Since it directly affects image sharpness, color fidelity, print speed, and maintenance cost, selecting the right print head is a key decision for any printing system.

Types of Print Heads Used in Digital Printing

When you’re looking for the best print head, you’ll encounter two major technologies. Understanding them helps you match the head to your application.

-

Piezoelectric Print Heads

The way these work is pretty cool. Each nozzle has a little piezo-electric bit behind it. When you apply some voltage, it flexes or moves in response, which forces a tiny drop of ink right out of the nozzle.

Advantages: excellent control of drop size, works with more types of inks, and tends to last longer.

Disadvantages: high cost, lower speed compared to simpler models

-

Thermal Print Heads

In this type, the nozzle uses a teeny tiny resistor to heat the ink, creating a bubble that forces the ink out of the nozzle.

Advantages: simpler design, lower cost

Disadvantages: less control over drop size, fewer compatible ink types

Key Factors to Consider When Choosing a Print Head

Compatible Inks

You must make sure that the print head you are using is compatible with the type of ink you want to use. Wrong ink can cause clogging, poor performance, or failure.

Resolution and Droplet Size

Smaller droplets make fine detail and smooth gradients. If you’re printing items with fine text, intricate graphics, or high fidelity images, droplet size and resolution matter.

Conversely, if you’re printing larger items like big outdoor signs where fine detail is not that important, you might let go of a bit of resolution for speed and coverage.

Speed and Productivity

Nozzles per head, drop frequency, and width of the print head; all these factors affect how fast your printer can print. Higher speed may reduce cost per piece, but you would have to compromise on detail in that case. You should balance speed with quality depending on your business model.

Durability and Maintenance

Print heads are wear items. How long a head lasts, how easily it can be cleaned, and how much downtime it causes are very important factors in your decision. For example, a head designed for high-volume production may need more robust designs.

Total Cost of Ownership (TCO)

Don’t just look at the upfront cost whilst making your decision. You should consider a printhead's life span, its maintenance, the potential for downtime, ink waste, and replacement cost. A cheaper print head can cost you more because of these factors.

Compatibility with your Printer and Workflow

Make sure the print head fits your printer model, works with your RIP software, supports your product size, and has spare parts and after-sales support available.

Support and brand reliability

Reputable brands frequently have better service, replacement availability, and known reliability. Warranty/after-sales support matters when you run business operations.

Popular Print Head Brands and Their Features

Here are some name brands and what they bring to the table when you’re shopping for the best print head.

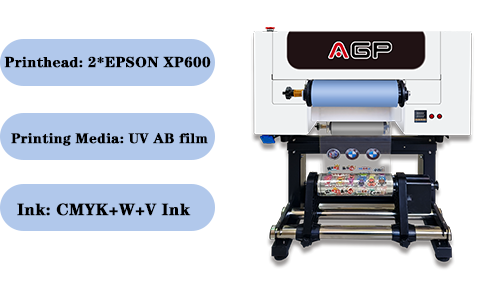

Epson

They're well known for their piezo-electric print heads - the I3200 series, for example - which are a popular choice for sublimation printing and high-res work.

Ricoh

Industrial-level print heads from Ricoh are often used in wide-format printers and in special applications where reliability and performance are top priority.

Xaar

Popular in industrial inkjet for large-format systems for bigger prints and bigger batches.

HP

Uses thermal inkjet technologies in many of its commercial systems; oriented more toward aqueous inks and general use. When assessing these brands, look at model-specific specs: nozzle count, drop size, compatible inks, maintenance schedule, and cost per head.

Application-Based Selection: Matching the Print Head to Your Business

To pick the “best print head,” you must match your needs. Here are a few possibilities:

High-resolution graphics or sublimation:

Choose a piezo-electric head with droplet control, small drop size, and good ink compatibility.

Large format signs or bigger batches:

A head with higher speed, wider width, may accept larger droplets and fewer passes, possibly a thermal type if inks allow.

Diverse substrates or specialty inks (e.g., white ink, UV, solvent):

Pick a head that is certified for those inks and built for such environments.

Budget-conscious startup:

If you want to start small, go with a lower resolution, but pick a reliable print head with good parts and after-sales support.

Conclusion

Choosing the right print head for your digital printing business is more than just making a purchase; it's a crucial business decision that needs some serious thought beforehand. Put in the time to get to know print heads and look after them properly, and you'll get the most out of them.

By getting to know the different types of print heads out there, you can make a more informed choice based on what matters most to you, like which inks can be used with the print head, how sharp your prints can be, how fast you can churn them out, and what the cost is going to be. That way, you can pick a print head that'll give you the same level of quality every time.