Why UV DTF Printers Are the Best Sticker Printing Machines in 2025

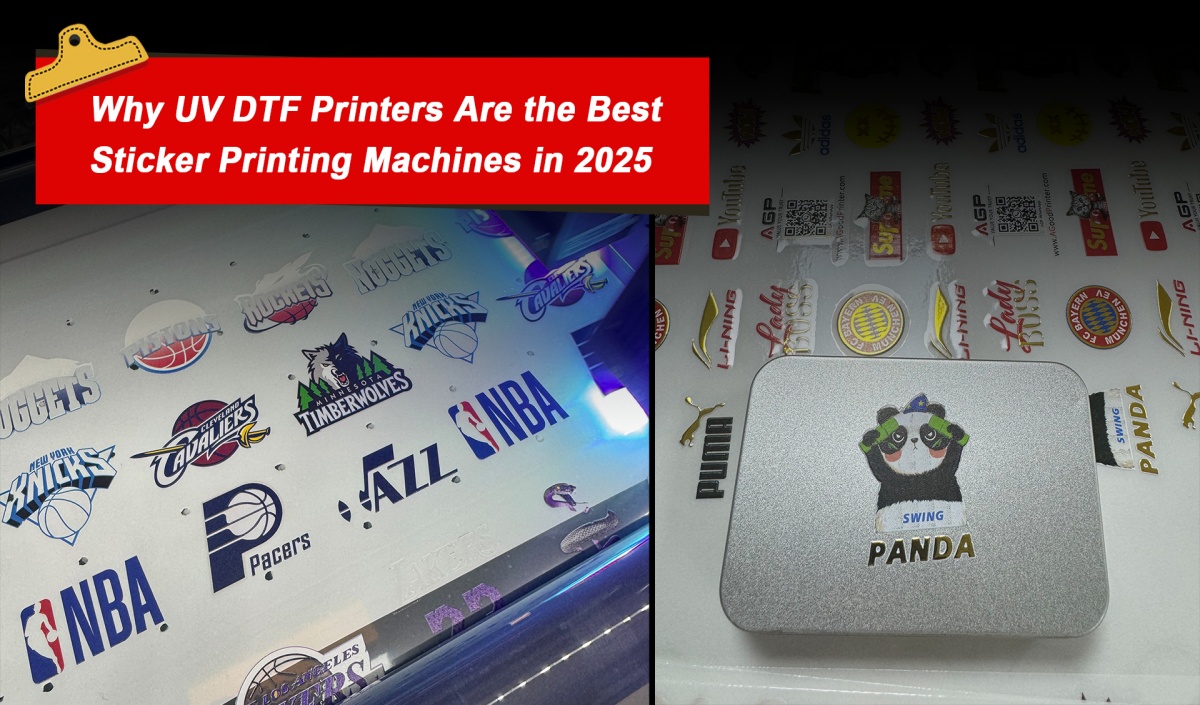

In today’s rapidly expanding digital printing market, sticker production has become one of the most profitable and versatile business segments. From branding labels and product packaging to personal customization and creative merchandising, the demand for fast, high-quality sticker output continues to grow. Among all available solutions, the UV DTF Printer has taken the spotlight as the most advanced and reliable sticker printing machine. Offering bright colors, long-lasting durability, and compatibility with a wide range of materials, the UV DTF system has reshaped how businesses approach custom sticker production.

In this article, we’ll take a fresh look at how AGP’s UV DTF Printer stands out in sticker printing—from its working principles to its core advantages and the industries that rely on it every day.

What Is a UV DTF Printer?

A UV DTF Printer is a hybrid technology that merges the strengths of UV printing with Direct-To-Film transfer processes. Instead of printing directly onto an object, the design is printed onto a specialized DTF film—commonly referred to as A film—and then laminated with B film. Once transferred, the sticker adheres securely to a wide variety of materials, maintaining its clarity and color vibrancy over time.

The “UV” refers to UV-curable inks that harden instantly when exposed to UV-LED light. These UV inks are known for their strong adhesion, water resistance, and fade resistance. The “DTF” component ensures that the printed design can be transferred to complex shapes and non-flat surfaces, making the process both flexible and efficient.

AGP has been deeply involved in UV and DTF technology for years, offering UV DTF printers that combine precision, stability, and user-friendly operation—making them ideal for businesses that need professional-grade sticker production.

How Does a UV DTF Printer Work?

Although the UV DTF printing workflow includes several steps, it is far more efficient and cleaner than traditional screen printing or vinyl cutting. The process generally includes:

-

Prepare the Artwork

Users create or import their designs into RIP software, allowing precise color control, layering setup, and white ink configuration. -

Print onto A Film

The machine prints CMYK color layers, followed by white ink and a varnish layer depending on the sticker effect. The UV ink cures instantly during printing, preventing smudging and shortening production time. -

Laminate with B Film

Once the A film is printed, it is laminated with B film to form a pressure-sensitive sticker. This A&B film combination creates strong adhesion without the need for heat pressing. -

Transfer to the Final Object

Cut the sticker, place it onto the product surface, press lightly to remove air bubbles, and peel off the B film. The result is a glossy, durable sticker with a tactile texture and premium appearance.

This entire process delivers a smooth workflow suitable for both small custom orders and large-scale production.

Why UV DTF Printer Is the Best Sticker Printing Machine Today

High-Level Print Quality

A UV DTF Printer produces vivid colors, crisp linework, and finely detailed patterns thanks to its sophisticated UV ink layering system. The cured UV ink resists peeling, cracking, and fading even after long-term use. Whether printing intricate logos or large-format stickers, the output maintains exceptional clarity and visual impact.

Outstanding Durability

UV DTF stickers can withstand outdoor exposure, moisture, and physical abrasion. They remain intact on items such as water bottles, helmets, laptops, motorcycles, or textured surfaces. This durability is one of the reasons why UV DTF technology has become the preferred choice for commercial-grade sticker production.

Wide Material Compatibility

One of the strongest advantages of a UV DTF Printer is its material versatility. It allows sticker application on surfaces that UV flatbed printing struggles with, including:

-

Plastics (ABS, PP, PET)

-

Glass

-

Metal

-

Leather

-

Wood

-

Paperboard

-

Ceramic

Whether you want full-color labels, decorative decals, packaging elements, or promotional stickers, UV DTF printers can cover all demands with minimal material limitation.

No Pre-Treatment Required

Unlike many other printing technologies, UV DTF requires no coating, spraying, or priming. There is no need for screens, plates, or setup time. This makes the process incredibly convenient for beginners and allows businesses with limited space to start sticker production with minimal preparation.

Environmentally Friendly and Cost-Efficient

UV ink contains fewer VOC emissions, making the UV DTF printing process cleaner and more eco-friendly. UV curing consumes less energy than heat-based systems, reducing operating costs.

In addition, the low ink consumption and high transfer success rate make UV DTF an economical choice for businesses aiming to lower production costs while maintaining excellent sticker quality.

Applications of UV DTF Stickers Across Industries

The versatility of UV DTF stickers allows them to be used across numerous industries and product categories:

Branding & Promotional Use

Companies rely on UV DTF stickers for product packaging, marketing campaigns, and branded merchandise. Stickers can feature barcodes, logos, messaging, QR codes, and full-color illustrations.

Personalized Item Decoration

Custom stickers for phones, tablets, mugs, game consoles, and laptops are extremely popular. UV DTF makes it easy to produce personalized gifts and lifestyle items.

Automotive & Outdoor Decoration

UV DTF stickers can endure sunlight and rain, making them ideal for motorcycles, cars, helmets, and outdoor equipment.

Industrial Labels & Product Identification

Factories use UV DTF labels for warning stickers, instruction labels, durable tags, and equipment indicators.

Creative Businesses & Artists

Designers and small studios can print unique stickers for scrapbooks, journals, art merchandise, and online store sales.

Conclusion

A UV DTF Printer provides unmatched print quality, durability, and material compatibility, making it the best solution for modern sticker production. Whether your business focuses on commercial branding, personalized goods, or large-scale manufacturing, UV DTF printing offers a cost-effective and highly flexible way to create premium stickers.

AGP, as a professional manufacturer in the digital printing industry, delivers advanced UV DTF printing solutions designed to support both small businesses and industrial operations. If you’re looking to upgrade your sticker production capabilities, AGP’s UV DTF printers are ready to help you move to the next level.