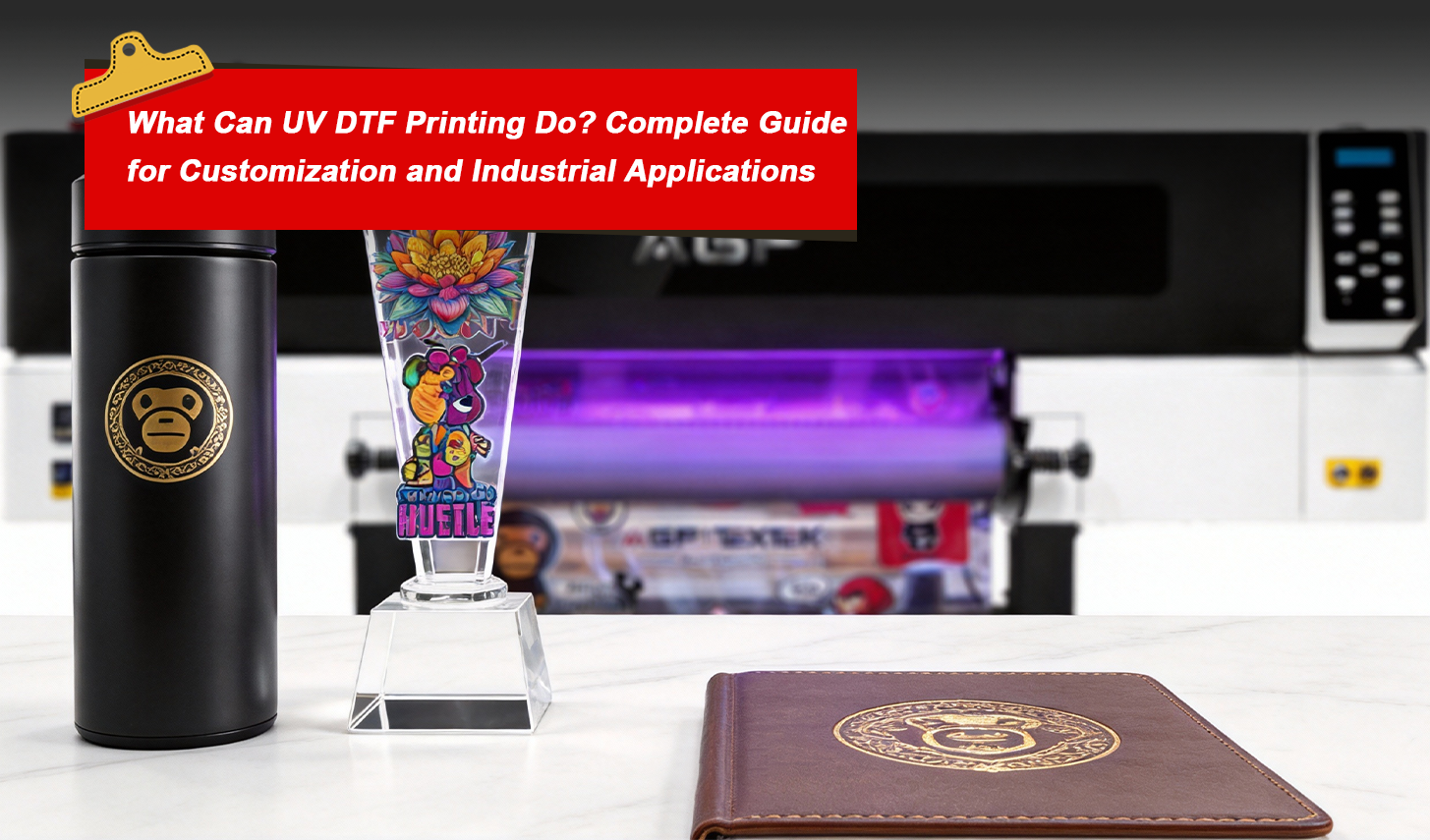

What Can UV DTF Printing Do? Complete Guide for Customization and Industrial Applications

The global customization market is entering a new growth stage. From consumer goods and branding labels to creative products and industrial identification, demand for high-quality surface decoration continues to rise.

In this fast-changing environment, UV DTF printing is quickly becoming one of the most competitive digital printing solutions. Compared with traditional UV printing, screen printing and adhesive vinyl solutions, UV DTF printing offers a unique balance between flexibility, production efficiency and visual performance.

This article provides a practical and business-oriented explanation of what UV DTF printing can really do, how it works, where it can be applied, and why more manufacturers and print service providers are now investing in professional UV DTF printer systems from AGP.

What Is UV DTF Printing?

UV DTF printing, short for UV Direct to Film printing, is a digital transfer technology that prints images onto a special release film and then transfers the printed graphics directly onto almost any surface.

Unlike conventional UV flatbed printing, which requires the substrate to be placed inside the printer, UV DTF printing technology allows graphics to be applied after printing. This makes it especially suitable for irregular, curved and hard-to-position objects.

A complete UV DTF printing solution typically includes:

-

UV DTF printer

-

UV ink system

-

special UV DTF film (A film and B film)

-

Laminating and transfer workflow

The final result is a ready-to-apply UV transfer sticker with strong adhesion, vivid color and premium surface texture.

For many customization businesses, UV DTF printing bridges the gap between high-end UV printing and flexible sticker decoration.

How UV DTF Printing Technology Works

From a production perspective, the UV DTF printing workflow is simple, stable and highly scalable.

First, artwork is prepared through professional design software and processed by RIP software for color management and white ink layering.

Next, the UV DTF printer prints the image onto a dedicated release film using:

-

CMYK ink

-

white ink

-

optional varnish ink

All inks are instantly cured by UV LED lamps during printing.

After printing, the image layer is laminated with a transfer film. The finished UV DTF transfer can then be stored, transported and applied later.

During application, the operator only needs to:

-

position the transfer

-

apply light pressure

-

peel the carrier film

The printed image remains firmly attached to the surface.

This workflow is one of the reasons why UV DTF printing machines are becoming popular for on-demand production, short-run orders and distributed manufacturing.

Core Capabilities of UV DTF Printing

The real strength of UV DTF printing lies in three core capabilities: material adaptability, visual performance and customization scalability.

These capabilities make UV DTF printing suitable for both consumer and industrial markets.

Material and Application Versatility

One of the most valuable capabilities of UV DTF printing is its outstanding substrate compatibility.

UV DTF transfer graphics can be applied to:

-

glass

-

acrylic

-

plastic

-

metal

-

coated wood

-

ceramic

-

leather

-

painted surfaces

-

packaging materials

Even curved bottles, cups, electronic housings and decorative accessories can be decorated easily.

Compared with traditional UV flatbed printers, UV DTF printing eliminates the limitations caused by:

-

object thickness

-

height differences

-

uneven surfaces

For customization businesses, this means:

-

one UV DTF printer can serve multiple product categories

-

no additional fixtures are required

-

product development cycles become significantly shorter

In practical production environments, UV DTF printing is widely used for:

-

custom logo transfers

-

brand stickers

-

decorative labels

-

personalized surface graphics

Print Quality, Durability and Visual Effects

Another important capability of UV DTF printing is its high and consistent visual output.

Modern UV DTF printers equipped with precision printheads deliver:

-

sharp text edges

-

smooth gradients

-

high color density

-

accurate white ink layering

Because UV inks are cured instantly, the image layer becomes highly resistant to:

-

moisture

-

abrasion

-

mild chemicals

-

daily handling

This makes UV DTF printing especially suitable for long-term branded products and functional labeling.

In addition, UV DTF printing supports:

-

spot varnish effects

-

raised texture printing

-

3D visual effects

For brands looking to differentiate their packaging and product appearance, UV DTF printing technology enables premium decorative finishes without complex production steps.

Customization and Personalization Power

Customization is one of the main driving forces behind the rapid growth of UV DTF printing.

UV DTF printers are designed to handle:

-

single-piece customization

-

multi-design short runs

-

variable data printing

This is particularly important for:

-

personalized gifts

-

promotional merchandise

-

boutique product lines

-

online customization platforms

Because no screen making or plate production is required, UV DTF printing allows businesses to switch designs instantly without additional setup cost.

From a commercial perspective, this creates new profit models such as:

-

personalized name printing

-

limited edition product releases

-

influencer branding projects

The flexibility of UV DTF printing directly supports modern personalization strategies.

Key UV DTF Printing Applications

Thanks to its technical characteristics, UV DTF printing is now being applied across multiple industries.

Consumer Product Decoration

In the consumer market, UV DTF printing is widely used for:

-

customized phone cases

-

water bottles

-

cosmetic containers

-

home accessories

-

gift items

Small workshops and online sellers can use UV DTF printers to build flexible product catalogs without investing in multiple production machines.

Industrial and Commercial Identification

For industrial users, UV DTF printing is applied for:

-

product labels

-

equipment identification tags

-

safety markings

-

barcode and QR code labeling

Because UV DTF printing offers stable adhesion and high durability, it performs well in light industrial environments where traditional stickers may fail.

Creative and Design Industries

Design studios and artists increasingly adopt UV DTF printing for:

-

limited art series

-

decorative objects

-

boutique packaging projects

-

exhibition products

The ability to reproduce fine details and special visual effects allows UV DTF printing to meet creative expectations without sacrificing production efficiency.

Business Advantages of UV DTF Printing

From a business management viewpoint, UV DTF printing brings several operational benefits.

High Production Efficiency and Cost Control

UV DTF printing reduces production steps compared with traditional decoration processes.

There is no need for:

-

complex fixture preparation

-

repeated substrate loading

-

manual coating processes

Lower setup cost and shorter production cycles make UV DTF printing extremely attractive for:

-

small batch production

-

fast order delivery

-

flexible project scheduling

Eco-Friendly and Low-Waste Production

Modern UV DTF printing uses UV-curable inks with low VOC emissions.

In addition, on-demand production significantly reduces:

-

excess inventory

-

material waste

-

rework caused by incorrect positioning

For companies seeking sustainable manufacturing practices, UV DTF printing supports cleaner and more controlled production workflows.

Production Flexibility for Different Order Scales

Whether producing one customized piece or several thousand transfers, UV DTF printers maintain consistent output quality.

This allows businesses to accept:

-

personalized retail orders

-

wholesale projects

-

seasonal promotional campaigns

without adjusting equipment configuration.

Future Development of UV DTF Printing

The future of UV DTF printing is closely linked to technological innovation and market expansion.

Continuous Equipment and Ink Improvements

In the coming years, UV DTF printing systems are expected to benefit from:

-

improved white ink stability

-

higher print speeds

-

smarter RIP software integration

-

more reliable film compatibility

Manufacturers such as AGP continue to invest in R&D to improve machine stability and operator experience.

Expansion into New Industry Segments

As more manufacturers recognize the advantages of UV DTF printing, the technology is expanding into:

-

customized packaging decoration

-

retail branding displays

-

interior decoration components

-

small appliance surface decoration

The adaptability of UV DTF printing makes it suitable for emerging customized manufacturing ecosystems.

Conclusion

UV DTF printing has become one of the most flexible and commercially valuable digital printing technologies in today’s customization market.

By combining:

-

material versatility

-

durable UV ink performance

-

strong personalization capabilities

-

efficient production workflows

UV DTF printing technology enables businesses to respond faster to market demands while maintaining premium product quality.

Whether you are operating a customization workshop, a branding service provider, or a manufacturing company seeking surface decoration solutions, a professional UV DTF printer system from AGP can significantly expand your product possibilities and competitive advantage.

If you are considering building or upgrading your UV DTF printing production line, AGP offers complete UV DTF printer solutions and technical support to help your business grow sustainably in the global digital printing market.