How Visual Positioning UV Printers Transform Accuracy and Productivity in 2025

In recent years, UV printers with visual positioning have become one of the most talked-about technologies in the digital printing industry. As manufacturers seek higher efficiency and improved accuracy, this new type of UV printer — equipped with an intelligent camera positioning system — is quickly gaining popularity. Instead of requiring operators to place items in fixed positions manually, the machine can automatically detect the shape, position, and angle of each product, then match the print file with perfect alignment.

So, what exactly is visual positioning technology? How does it work? And why are so many factories upgrading to this type of UV printer? This article breaks it down clearly and practically, helping you understand whether this technology is right for your business.

What Is Visual Positioning in UV Printing?

A visual positioning UV printer uses a built-in industrial camera system to analyze the item placed on the printing platform. The camera captures the product’s coordinates, outline, and orientation. Then the software automatically adjusts the print file so the UV printer can start printing exactly on the correct spot.

Unlike traditional UV printers that rely on fixed templates or jigs, visual positioning allows you to place products randomly on the bed — the machine will still print precisely where it should.

This technology is widely used in printing phone cases, acrylic signs, promotional items, packaging components, customized gifts, metal plates, keychains, and other irregular or batch-produced items.

How Does Visual Positioning Work? (Simple Explanation)

The working process includes four key steps:

-

Camera Scanning

The high-resolution camera above the bed scans all items placed on the platform. -

Shape Recognition

The software detects the outline, position, orientation, and size of each product. -

Auto File Matching

The system automatically aligns the print artwork to each item’s exact position. -

Accurate Printing

The UV printer starts printing with micron-level accuracy, without manual adjustment.

This combination of camera + software + UV printing head creates a highly automated workflow, especially useful for mass production.

Advantages of Visual Positioning UV Printers

1. No Need for Positioning Fixtures

Traditional UV printers require molds or jigs to keep each product in the correct spot.

A visual positioning UV printer removes this step completely, saving time and cost.

2. Faster and More Efficient Workflow

Operators only need to place the items on the platform — anywhere.

The system automatically recognizes them, reducing manual labor and boosting productivity.

3. Higher Printing Accuracy

The camera-guided alignment ensures consistent positioning, even for small or irregular objects such as badges, USB drives, labels, packaging lids, and accessories.

4. Lower Labor Cost

Since the machine does the alignment work, one operator can handle more tasks at once, especially during large batch production.

5. Suitable for Mixed-Size or Randomized Items

Products of different sizes/shapes can be placed together.

The system recognizes each one individually and prints accordingly.

6. Reduced Error Rate

Manual alignment often results in shifting or misprints.

Visual positioning minimizes rework and ensures better quality control.

Where Can Visual Positioning UV Printing Be Used?

This technology fits industries requiring fast batch customization, including:

-

Phone case production

-

Electronics accessories

-

Acrylic and signage printing

-

Gifts & promotional items

-

Packaging components

-

Metal and hardware products

-

Plastic parts

-

Consumer goods customization

-

Small-scale branding products

-

Crafts and decorative items

In any application involving multiple small objects or high-speed alignment, visual positioning saves both time and labor.

Why More Factories Are Upgrading to Visual Positioning Systems

Factories increasingly need:

-

Shorter production cycles

-

Higher accuracy

-

Lower labor requirements

-

Flexibility in product types

-

Consistency for bulk orders

A visual positioning UV printer meets all these demands, making it an ideal choice for modern digital printing production lines.

AGP’s Visual Positioning UV Printer Solutions

As a manufacturer with 12 years of digital printing experience, AGP (Henan Yoto Machinery Co., Ltd.) offers UV printers equipped with:

-

Industrial camera systems

-

High-precision auto alignment

-

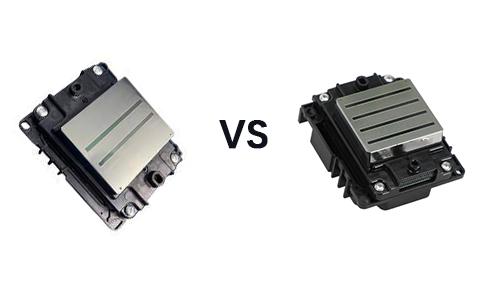

Epson I3200-U1 / Ricoh printheads

-

Advanced control software

-

Support for materials such as acrylic, metal, glass, wood, leather, plastic, and more

Our visual positioning UV printers are designed for industrial-level stability, fast job switching, and maximum productivity.

If your factory needs higher efficiency or handles many small customized items daily, this technology will significantly upgrade your workflow.

Final Thoughts

Visual positioning UV printers represent a major step forward in digital printing automation. By combining smart recognition technology with UV printing, manufacturers can achieve:

-

Faster production

-

Reduced labor

-

Higher accuracy

-

Better consistency

-

More flexible customization

For businesses aiming to expand their customization services or improve production efficiency, visual positioning is not just a trend — it’s the future of UV printing.