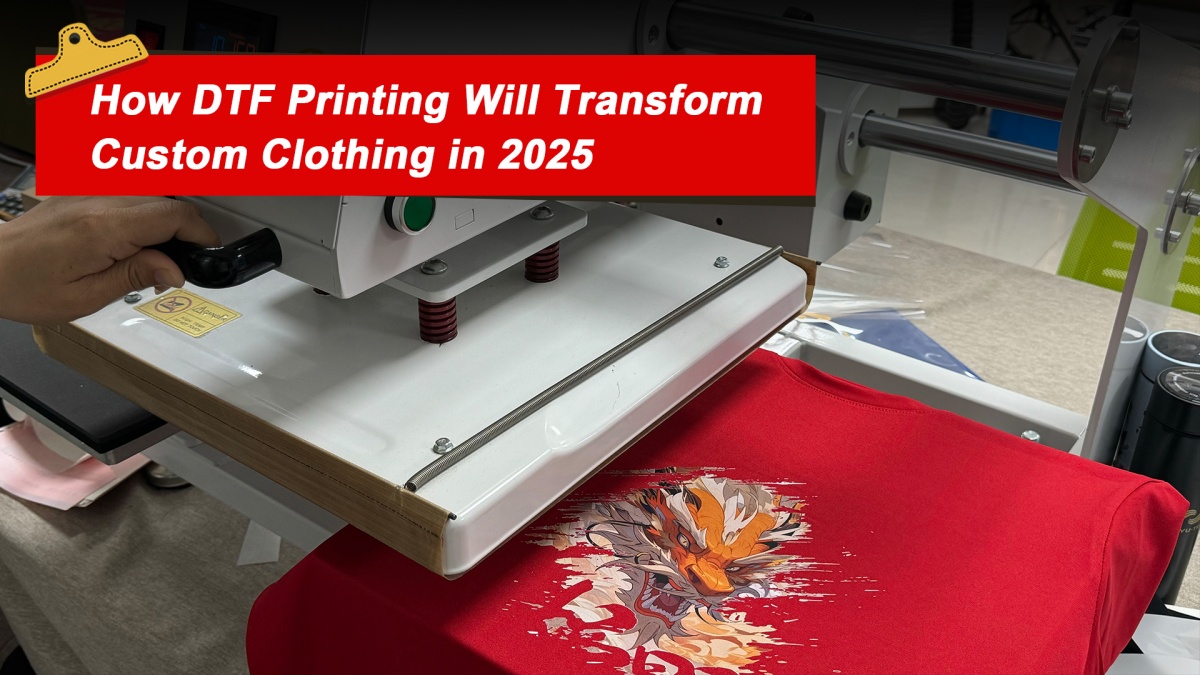

How DTF Printing Will Transform Custom Clothing in 2025

The world of DTF custom clothing is entering a new phase—faster, cleaner, smarter, and far more design-driven than ever before. As digital garment decoration continues to grow globally, DTF printing outperforms older technologies in terms of flexibility, durability, and cost efficiency. With AGP expanding its innovation in the DTF market, many transformative trends are forecasted for 2025. This article explores the shifts that will define the next stage of custom apparel production, from sustainability to AI-driven creativity, on-demand fulfillment, and cross-technology integration.

Sustainability Takes the Lead in DTF Apparel Production

Eco-Friendly DTF Inks & Materials

Sustainability is no longer a niche trend—it is becoming a mandatory requirement in the DTF custom apparel industry. Consumers expect brands to use greener materials, which has led the DTF market toward water-based DTF inks, low-VOC formulations, biodegradable DTF film, and energy-efficient curing solutions.

A major sustainability milestone is the rise of powderless DTF technology. Unlike traditional DTF workflows using DTF hot melt powder, powderless systems use a specialized adhesive coating, dramatically reducing powder waste and improving environmental compliance. AGP’s upcoming powderless DTF systems are designed to meet stricter eco-standards while maintaining the vivid colors and strong wash resistance DTF printing is known for.

Circular Fashion & Upcycling with DTF

Circular fashion is gaining momentum—repurposing old garments, reprinting designs, and extending product lifecycles. Since DTF printers can print on nearly any fabric, including cotton, polyester, denim, blends, and even recycled textiles, the technology supports upcycling perfectly.

Brands can customize second-hand clothing through DTF transfers, offering low-cost personalization while embracing sustainable fashion.

Advanced Technology Integration Will Reshape Workflows

AI Design Integration

In 2025, AI will be one of the biggest catalysts for change in DTF custom clothing. AI-powered design systems will allow creators to:

-

Generate artwork in seconds

-

Predict trending graphics

-

Optimize color layouts

-

Adjust patterns for different garment sizes

-

Automate production-ready vector files

AGP has begun integrating intelligent automation into its DTF solutions, enabling smoother workflows from design creation to final heat transfer printing.

Smarter DTF Printers & Cloud Connectivity

DTF machines are moving toward remote diagnostics, predictive maintenance, and cloud-based print management. These features help shop owners track production, analyze ink usage, and manage multiple orders efficiently—crucial for scalable custom apparel businesses.

Hyper-Personalization Becomes the Core Driver of Market Demand

On-Demand Production for Apparel Businesses

The global demand for personalized clothing continues to grow, and DTF printing is the perfect solution. Because DTF printers can produce:

-

small batches

-

unique prints

-

photo-quality graphics

-

fast turnaround orders

—brands can fulfill orders instantly without storing inventory. This on-demand customization model reduces waste and allows businesses to keep up with rapid market changes.

Online Customization & Global E-commerce

In 2025, more DTF businesses will move to online platforms where users can upload artwork, request custom DTF transfers, or order finished garments. With DTF’s high speed and easy workflow, it becomes simple to serve customers worldwide.

Shop owners benefit from a wider audience and faster production cycles—making DTF an essential tool for digital commerce.

Creative Design Approaches Will Shape Next-Gen Custom Apparel

Bold, Distinctive, High-Detail Visuals

Younger consumers prioritize personality-driven designs. Expect 2025 to bring more:

-

neon gradients

-

metallic-style effects

-

fine-line illustrations

-

mixed-media style graphics

-

high-contrast color palettes

DTF printing, especially with CMYK+W configurations, enables these visual trends with exceptional clarity. AGP’s printheads ensure high-resolution output, making it easier to create premium streetwear and fashion pieces.

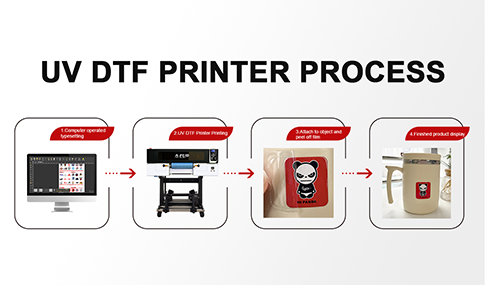

Combining DTF with Other Apparel Technologies

Hybrid workflows are emerging as one of the most exciting directions for apparel printing. By combining:

-

DTF + embroidery

-

DTF + cutting plotters

-

DTF + DTG printing

-

DTF + sublimation

businesses can create layered effects, textured finishes, and entirely new types of garment decoration. AGP’s hybrid solutions bridge these techniques, reducing manual labor and improving production speed.

Market Expansion Into Niche Segments & New Industries

Subculture Fashion & Youth Trends

Subculture styles—from anime to cyberpunk to graffiti-inspired graphics—are gaining mainstream attention. With DTF printing, brands can produce short-run collections for micro-communities without high costs. This ability gives online stores and independent designers a strong competitive edge.

Corporate Branding & Promotional Apparel

DTF is also transforming the promotional products sector. Companies rely on DTF transfers for:

-

logo uniforms

-

branded tote bags

-

event merchandise

-

sports team apparel

-

staff clothing

Because DTF designs resist cracking and fading, they deliver a more professional finish than many alternative printing methods.

What All These Trends Mean for the Future of DTF Custom Clothing

As 2025 approaches, the DTF apparel market is steering toward cleaner production standards, smarter technology, deeper personalization, and more expressive visual styles. Businesses that adapt early will stand out as consumer expectations shift toward uniqueness, eco-responsibility, and fast delivery.

For print shop owners, designers, and clothing brands, now is the ideal time to explore new opportunities in DTF custom clothing. Whether you produce in-house DTF transfers, run an online apparel store, or serve local businesses, AGP’s latest DTF machines and consumables will help you scale efficiently and stay ahead of the competition.

If you’re ready to upgrade your workflow or explore the newest DTF technology, AGP can support you with advanced printers, expert guidance, and reliable supplies tailored for the next generation of custom apparel.