DTF Printer Explained: Advantages, Workflow, and Printing Tips

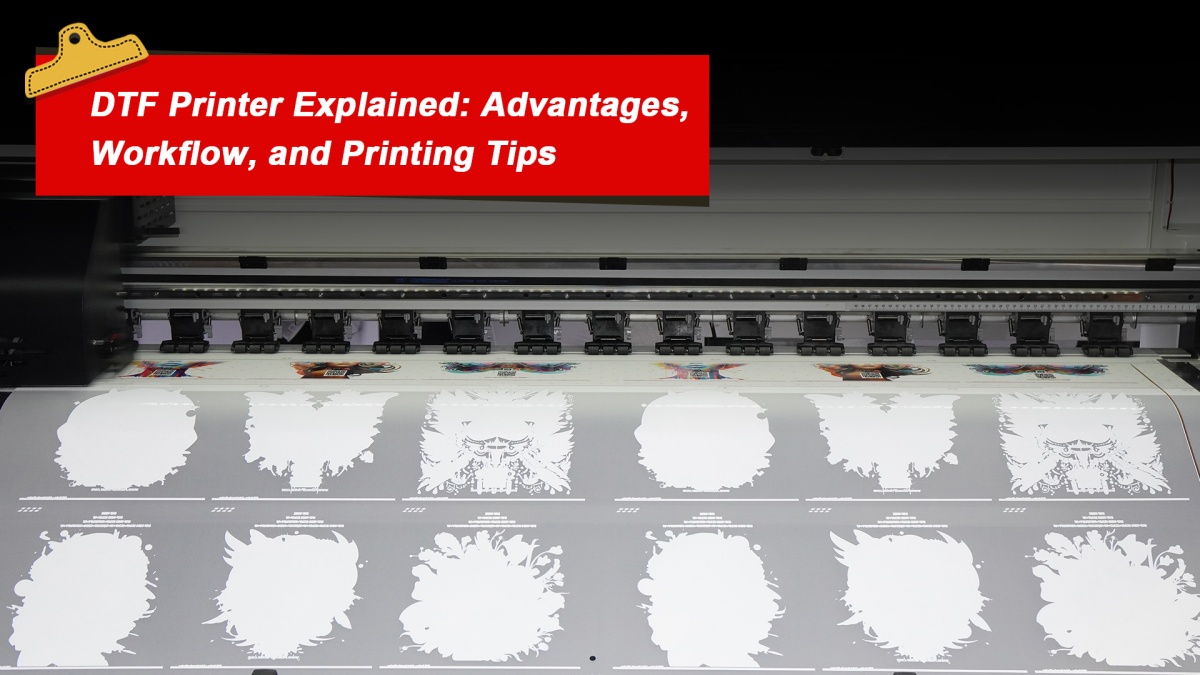

In the world of digital printing, a DTF printer (Direct to Film printer) has become a favorite for garment and custom apparel businesses. Unlike traditional screen printing or DTG (Direct to Garment) printing, a DTF printer prints designs onto a special DTF film first. This film, coated with adhesive powder, is then heat-transferred onto fabrics, creating vibrant, durable prints without direct ink application.

The DTF printing workflow is simple yet effective:

-

Design Creation – Patterns and images are designed digitally.

-

Film Printing – The design is printed onto transparent DTF film using high-quality inks.

-

Powder Coating – Adhesive powder is applied to ensure the design sticks.

-

Curing – The powder is cured using a heating process.

-

Heat Transfer – The design is transferred onto fabric using a heat press.

This method bypasses many limitations of conventional printers, offering high flexibility, efficiency, and consistency in printing intricate designs on a wide range of fabrics.

How DTF Printer Solves Conventional Printing Problems

Traditional printing methods, including screen printing and sublimation, often struggle with limitations:

-

Material restrictions – Certain inks only work on specific fabrics.

-

Complex setup – Time-consuming preparation and multi-step processes.

-

Limited color precision – Difficulty reproducing vibrant, intricate patterns.

With DTF printing, these problems are minimized. The printer works on both light and dark fabrics, doesn’t require pre-treatment, and delivers consistent color accuracy and sharp details. Small to medium production runs become more practical, with reduced waste and faster turnaround times. The prints also retain durability and washability, ensuring that the final garments maintain their quality through multiple washes.

Key Advantages of DTF Printer

The DTF printer has become indispensable in the textile and apparel industry because of the following benefits:

Vibrant, Accurate Colors

The digital pigment inks used in DTF printing ensure colors are rich, bright, and true-to-design. Logos, graphics, and detailed images come out exactly as intended.

Unlimited Design Flexibility

With DTF printing, almost any digital pattern can be transferred onto fabric. This flexibility allows brands to experiment with complex patterns, seasonal collections, and personalized designs, giving a competitive edge in custom apparel printing.

Excellent Wash and Rub Resistance

DTF prints have strong adhesion, preventing peeling, cracking, or fading. Garments withstand repeated washes, making this ideal for fashion, home textiles, and custom gifts.

Soft Hand Feel

Unlike traditional pigment or screen printing, DTF prints integrate seamlessly into the fabric, preserving softness and comfort. Customers enjoy the premium feel without harsh textures.

Cost-Effective Production

The initial investment is affordable compared to large screen printing setups. Businesses can start with small digital setups, a DTF printer, heat press, and basic workflow, yet achieve high-quality, commercial-ready prints.

Eco-Friendly Printing

DTF printing generates minimal waste and uses less water in post-processing. Its efficiency and sustainability make it appealing for environmentally conscious brands.

Why DTF Printer is Ideal for Garment Industry

DTF printers excel in the apparel sector due to their versatility, reliability, and low-maintenance requirements. They can print on cotton, polyester, blends, and more, handling both light and dark fabrics without pre-treatment.

Custom t-shirts, hoodies, tote bags, and small batches of promotional items can all benefit from DTF printing. For startups or established businesses, investing in a DTF printer increases productivity, reduces overhead costs, and allows rapid response to market trends, ensuring garments meet professional standards while satisfying consumer demands.

Selecting the Right DTF Printer

When choosing a DTF printer, consider the following:

-

Printing Requirements: Volume, fabric type, and design complexity.

-

Print Size & Resolution: Ensure the printer can handle large or multi-layer designs.

-

Ink and Film Quality: High-quality DTF inks and adhesive films improve durability.

-

Software Compatibility: Ensure the printer works seamlessly with your design software and RIP systems.

-

Maintenance & Support: Reliable after-sales support can save time and prevent downtime.

-

Cost Efficiency: Factor in running costs, consumables, and electricity for sustainable ROI.

By understanding your production goals and the features of each printer model, you can select the best fit for your business. AGP offers a variety of DTF printers to suit different scales, from small studios to industrial setups.

Real-World Applications of DTF Printing

DTF printing is transforming custom apparel production. Examples include:

-

Small businesses producing personalized gifts or local merchandise.

-

Event organizers printing high-quality conference t-shirts and banners.

-

Fashion designers creating small-batch collections with intricate patterns.

-

Corporate branding with durable, professional logos on uniforms or promotional items.

The combination of digital pigment printing, heat transfer technology, and adhesive DTF films ensures that designs stay vibrant, detailed, and long-lasting, even on challenging fabrics.

Conclusion

The DTF printer represents a modern solution for custom apparel printing. Its ability to deliver high-quality prints, vibrant colors, and versatile designs makes it a key tool for any business looking to scale efficiently. From startups to large enterprises, DTF printing enhances creativity, reduces production costs, and ensures customer satisfaction.

When exploring options, always evaluate printer specifications, consumables, workflow compatibility, and after-sales support. Partnering with a reliable manufacturer like AGP ensures you get cutting-edge technology, professional guidance, and long-term business growth.

For anyone entering the custom apparel printing market, a DTF printer is no longer just an option—it’s an investment in innovation, efficiency, and sustainability.