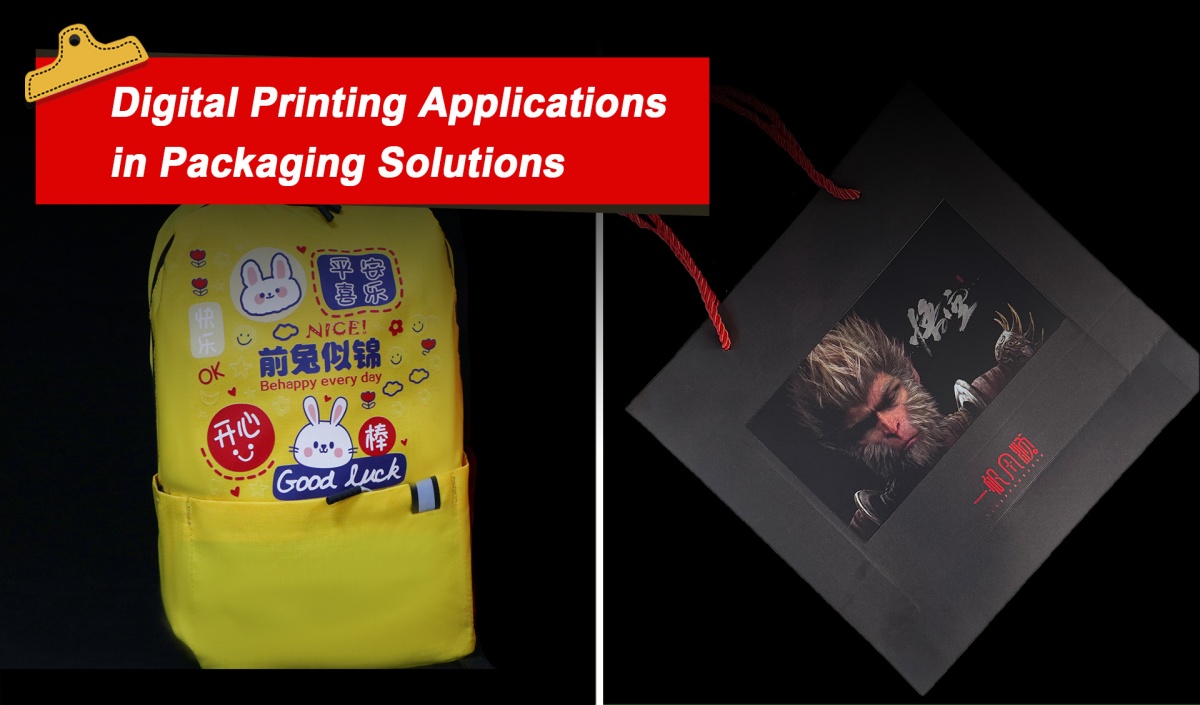

Digital Printing Applications in Packaging Solutions

In today’s fast-paced and ever-evolving packaging industry, digital printing has emerged as a game-changer. Unlike traditional printing methods, digital printing simplifies the process, reduces costs, and opens up new possibilities for packaging design. With increasing consumer demand for personalized packaging and shorter production runs, businesses are turning to digital printing as a more efficient and flexible solution. In this guide, we’ll take a closer look at how digital printing is transforming the packaging industry and why it’s the future of packaging.

What is Digital Printing?

Digital printing refers to the process of transferring digital designs directly onto substrates using various advanced printing technologies like UV printing and DTF printing. Unlike traditional printing methods, which require complex set-ups, such as plates or screens, digital printing works by directly applying the ink onto the surface of the material using digital files.

This innovation has revolutionized the packaging sector by offering high-quality prints, faster production times, and greater flexibility in design. Whether it's a small business looking to create personalized packaging or a large corporation needing to scale production, digital printing has become the go-to solution.

How Does Digital Printing Work?

The beauty of digital printing lies in its simplicity. The process involves sending a digital design file directly to a printing machine, where the ink or toner is applied directly to the substrate, whether it’s paper, plastic, metal, or fabric. Digital printing methods such as UV printing or DTF printing ensure vibrant, long-lasting colors and high detail on a variety of materials, without the need for costly setup or plate changes.

With UV printing, ink is cured immediately by ultraviolet light, ensuring that the print is dry and durable right after it’s printed. DTF printing, on the other hand, prints designs onto transfer films that can be applied to textiles or other materials, offering even more versatility for packaging designs.

Key Applications of Digital Printing in Packaging

The rise of e-commerce and the need for personalization has made digital printing indispensable for modern packaging. Here are some of the key applications where digital printing is making a significant impact.

E-commerce Packaging

The boom in online shopping has created a surge in demand for unique and personalized packaging. Digital printing allows e-commerce businesses to quickly print custom packaging solutions in small quantities, without the high upfront costs typically associated with traditional printing.

From custom-designed shipping boxes to personalized mailers, digital printing enables brands to create eye-catching, on-brand packaging that helps them stand out in a crowded marketplace. With digital printing, companies can print vibrant graphics, logos, or messages that resonate with customers, creating a memorable unboxing experience.

Labels and Stickers for Packaging

Labels are crucial in packaging as they provide vital product information, branding, and regulatory compliance. Traditional label printing often requires large print runs, which can be expensive and inefficient for businesses needing smaller quantities or frequent updates.

Digital printing solves this problem by allowing companies to print high-quality, detailed labels on-demand. Whether for food and beverage products, cosmetics, or health supplements, digital printing ensures that labels are vibrant, durable, and perfectly aligned with the brand’s image. Plus, digital printing’s flexibility means companies can easily make last-minute design tweaks or seasonal updates, ensuring their products are always fresh and in line with customer expectations.

Branding and Marketing Packaging

Packaging is more than just a container – it’s an essential part of your brand’s story. Digital printing gives companies the ability to produce highly detailed, visually appealing packaging that truly reflects their brand identity.

From limited-edition packaging to promotional gift boxes, digital printing provides endless opportunities for brands to showcase their creativity. What’s more, digital printing supports advanced techniques like variable data printing, which means each package can feature a different design or message. This opens up exciting possibilities for personalized packaging campaigns and promotional giveaways.

Custom and Luxury Packaging

Custom packaging has grown in importance for luxury products, with brands seeking ways to create exclusive, premium packaging that appeals to their target audience. Digital printing allows for intricate designs, embossing effects, and high-quality finishes that make packaging feel as luxurious as the product inside.

Whether it's a perfume box, a high-end bottle, or a designer gift package, digital printing offers an unmatched level of detail and precision. UV printing, with its ability to produce fine details and rich textures, is particularly popular in the luxury packaging market.

Advantages of Digital Printing in Packaging

While traditional printing methods have their place, digital printing brings a range of benefits to the table, making it a go-to solution for many businesses.

Faster Production and Shorter Lead Times

One of the biggest advantages of digital printing is its speed. Because there are no plates or screens to prepare, setup times are minimal, allowing businesses to get products to market much faster. This makes it ideal for short-run production, where companies can produce packaging in small quantities without compromising on quality.

Whether it’s a limited-edition run of products or a last-minute marketing campaign, digital printing ensures that packaging can be produced quickly, reducing lead times and speeding up the go-to-market process.

Cost-Effective for Small Runs

Traditional printing methods often require large print runs to be cost-effective. But for businesses that need smaller quantities, this can be an expensive proposition. Digital printing eliminates the need for high-volume printing, making it much more cost-effective for small businesses and brands that don’t require large quantities of packaging.

With digital printing, businesses can produce packaging in short runs, keeping costs down while maintaining high-quality results.

Eco-Friendly and Sustainable

As businesses become more conscious of their environmental impact, digital printing offers a more sustainable alternative to traditional printing methods. Digital printers use less ink and generate less waste, making them more eco-friendly. Additionally, digital printing supports the use of eco-friendly substrates, such as recycled paper and biodegradable plastics, helping brands meet their sustainability goals.

With UV printing, the ink cures instantly under UV light, reducing energy consumption compared to traditional drying methods. And because digital printing doesn’t rely on chemical-laden solvents, it’s a safer, more eco-conscious option for businesses.

Conclusion

Digital printing is transforming the packaging industry, offering businesses of all sizes a faster, more efficient, and cost-effective way to create high-quality, customized packaging. From e-commerce to luxury brands, digital printing provides endless possibilities for packaging design, enabling brands to create unique, personalized solutions that capture their audience’s attention.

With its ability to print on a wide range of materials, quick turnaround times, and eco-friendly benefits, digital printing is the future of packaging. Whether you're a small business owner or a large corporation, embracing digital printing can help you stay ahead of the competition and meet the evolving demands of today’s market.