3) Impushana inomswakama ngesikhathi sokuthuthumela

Indlela yokuxazulula inkinga: Ngemva kokuqeda izizathu zokugcina kanye nogesi omile, ungabheka ukuthi i-powder eningi ifafazwe yini, okubangela ukuthi i-powder esele ibe manzi ngesikhathi senqubo yokuthuthumela kwe-powder. Enqubweni ye-shaking powder, i-hot melt powder incike kakhulu ekumunceni amanzi ukuze inamathele kufilimu. Ekugcineni, ingxenye ye-powder kuphela ingafakwa ku-inki futhi inamathele ephethini, futhi i-powder eyengeziwe iyanyakaziswa. Phakathi nale nqubo, i-powder eyeqile idonswa umswakama weyinki futhi umswakama uyahwamuka ngesikhathi sokushisa kwangaphambili nokomisa kwefilimu, okungase kubangele ukuthi inamathele efilimu futhi inganyakazi.

Isixazululo: buyisela le ngxenye yempushana bese uyomisa. Faka uthuli ngempushana entsha. Ngesikhathi esifanayo, lawula inani lothuli phakathi nenqubo yokuthungula, hhayi kakhulu.

2. Ukuminyana kokumboza kwefilimu nokucoleka kwempushana

Ubuningi bokugqoka befilimu buncane futhi i-powder ilungile, okuzokwenza ukuthi i-powder ibambelele emgodini wokumboza wefilimu futhi ayikwazi ukunyakaziswa. Uma ubukhulu bokugqoka befilimu buphakeme, i-powder ayilungile kakhulu, i-powder ngeke ibambeke emigodini yokugqoka, futhi ukuthuthumela kwe-powder shaker ngeke kuyinyakazise.

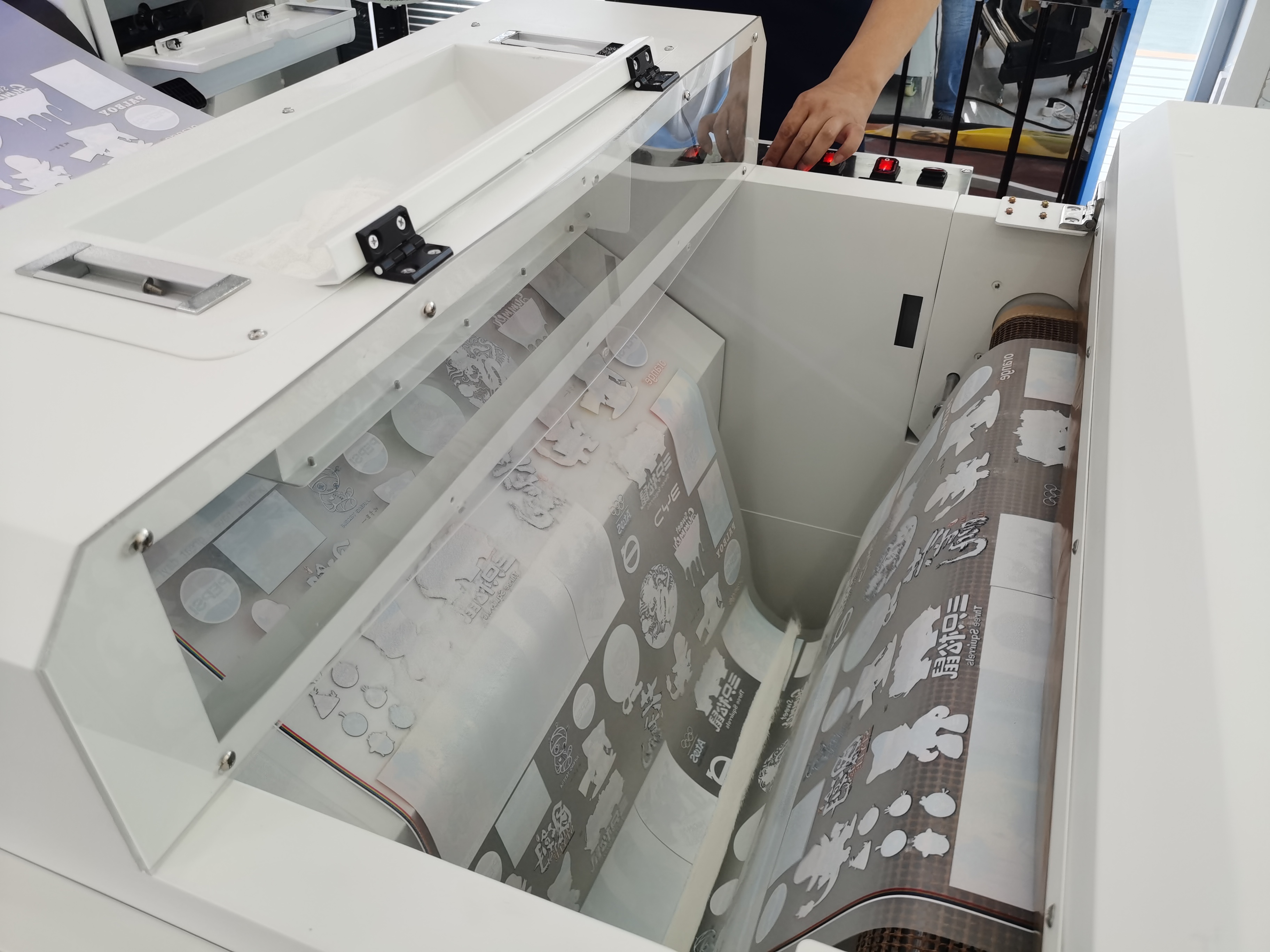

Isixazululo: Khulisa amandla okunyakazisa we-powder shaker, noma uthephe kanzima ngemuva kwefilimu uma unyakazisa impushana ngesandla. Ifuna abahlinzeki bamafilimu e-PET nezimpushana ezizinzile. Lo mbuzo awukona nje ukuqhathanisa ukuminyana kwe-coating kanye ne-fineness ye-powder, kodwa ngokuyinhloko kuncike ekuvumelaneni kwe-powder nefilimu. Ngemva kokuhlolwa okuningi nokuqhathanisa, i-AGP ikhethe ifilimu nempushana efaneleke kakhulu yephrinta ye-AGP DTF, elungele izimo ezihlukahlukene zohlelo lokusebenza nezindwangu. Siyakwamukela ukubonisana nokuthenga.

3. Isivinini sokuphrinta nokushisisa ngaphambili nangemuva

Lapho uphrinta, amakhasimende amaningi azovula imodi yokuphrinta enesivinini esikhulu. Lapho ifilimu ingakawufaki ngokuphelele uyinki, isivele ifinyelele inqubo yothuli nokuthuthumela, okuholela emswakama owedlulele. Uma ifilimu ingasomile, i-powder esele idonsa amanzi futhi ekugcineni inamathele efilimu.

Isixazululo: Lindela ukushisa kwangaphambili nangemuva kuze kufike ezingeni elilinganiselwe, bese uphrinta ngesivinini esingu-6pass-8pass, esingaqinisekisa ukuthi ifilimu ayimanzi futhi imunca uyinki ngokuqinile.