2. Pesvedzero yeinki ruzha kumhanya pane waveform

Kazhinji inokurumidza kupfuura inki inorema. Iko kumhanya kwenzwi remvura-based inki yakakura kudarika yeoiri-based inki. Kune iwo musoro wakadhinda wakafanana, kana uchishandisa dhizaini dzakasiyana dzeinki, iyo optimum wavelength mune yayo waveform inofanirwa kugadziridzwa. Semuyenzaniso, wavelength upamhi hwekutyaira mvura-based inki inofanira kuva diki pane iyo yeoiri-based inki.

3. Kufurira kweinki viscosity pane waveform

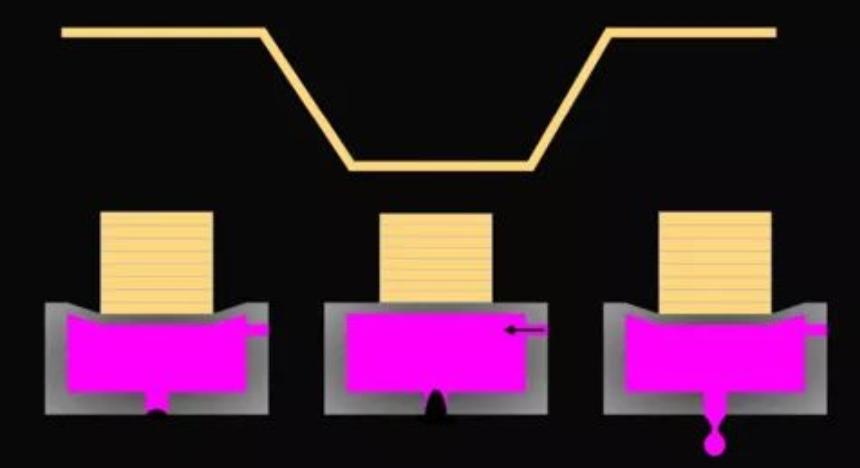

Kana iyo uv printer ichidhinda mune akawanda-poinzi modhi, mushure mekutanga kutyaira waveform yapera, inoda kumbomira kwechinguva yozotumira yechipiri waveform, uye kana yechipiri waveform yatanga zvinoenderana nekusarudzika kwechisikigo kweiyo nozzle pamusoro pekumanikidza. yekutanga waveform inopera. Shanduko inongoora kusvika zero. (Different inki viscosity ichakanganisa iyi nguva yekuora, saka ihwowo vimbiso yakakosha yekugadzikana inki viscosity kuti ive nechokwadi chekudhinda kwakagadzikana), uye zviri nani kubatanidza kana chikamu chiri zero, zvikasadaro wavelength yechipiri wave ichashandurwa. Kuti uve nechokwadi cheyakajairika inkjet, inowedzerawo kuoma kwekugadzirisa iyo yakakwana inkjet waveform.

4. Kufurira kweinki density kukosha pane waveform

Kana iyo ingi density kukosha kwakasiyana, kurira kwayo kumhanya kwakasiyanawo. Pasi pemamiriro ekuti saizi yepiezoelectric sheet yemusoro wakadhindwa yakatemerwa, kazhinji chete iyo pulse upamhi hurefu hweiyo drive waveform inogona kushandurwa kuti iwane yakanakisa pulse peak point.

Parizvino, kune mamwe ma nozzles ane yakakwira kudonha mumusika weUV printer. Iyo yekutanga muromo inodhinda 8 mm chinhambwe inogadziridzwa kune yakakwira waveform kuti idhindwe 2 cm. Zvisinei, kune rumwe rutivi, izvi zvichaderedza zvikuru kumhanya kwekudhinda. Kune rimwe divi, zvikanganiso senge inki inobhururuka uye mavara streaking zvinozoitika kakawanda, izvo zvinoda yakakwirira tekinoroji level ye UV printer vagadziri.