2. Mmetụta nke ink ụda ọsọ na waveform

Ọ na-adịkarị ngwa ngwa karịa ink dị arọ. Ọsọ ụda nke ink dabeere na mmiri dị ukwuu karịa nke ink dabeere na mmanụ. Maka otu isi mbipụta ahụ, mgbe ị na-eji njupụta ink dị iche iche, a ga-edozi ogologo ogologo ogologo kacha mma n'ụdị ifegharị ya. Dịka ọmụmaatụ, obosara obosara nke ink dabere na mmiri kwesịrị ịdị ntakịrị karịa nke ink dabere na mmanụ.

3. Mmetụta nke ink viscosity na waveform

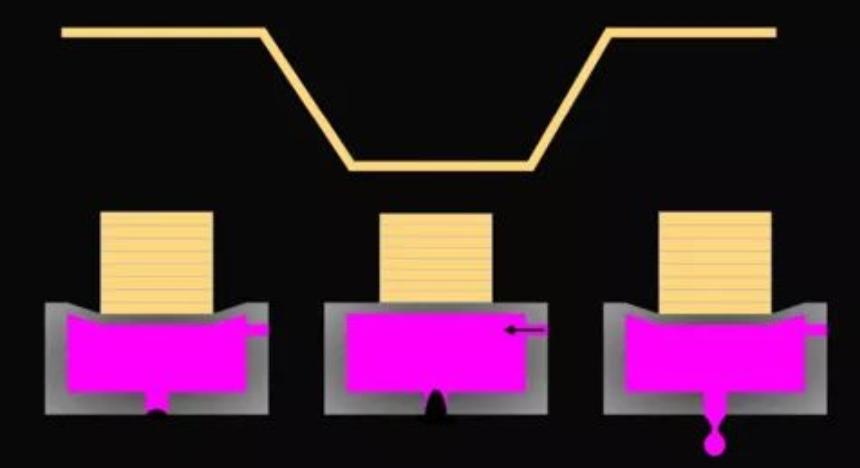

Mgbe uv ngwa nbipute na multi-point mode, mgbe mbụ ịkwọ ụgbọala waveform agwụ, ọ kwesịrị ka kwụsịtụ ruo oge na-ezipụ nke abụọ waveform, na mgbe nke abụọ waveform na-amalite na-adabere eke oscillation nke nozzle n'elu nrụgide mgbe. mbụ ifegharị agwụ. Mgbanwe ahụ na-agbada ruo efu. (Viscosity ink dị iche iche ga-emetụta oge ire ere a, yabụ na ọ bụkwa ihe dị mkpa na-ekwe nkwa maka viscosity ink kwụsiri ike iji hụ na mbipụta kwụsiri ike), ọ ka mma ijikọ mgbe usoro ahụ bụ efu, ma ọ bụghị ya, a ga-agbanwe ogologo ogologo nke ebili mmiri nke abụọ. Iji hụ na inkjet nkịtị, ọ na-abawanye ihe isi ike nke ịhazigharị ebili mmiri inkjet kacha mma.

4. Mmetụta nke ink njupụta uru na waveform

Mgbe uru njupụta ink dị iche, ụda ụda ya dịkwa iche. N'okpuru ọnọdụ na a na-ekpebi nha nke mpempe akwụkwọ piezoelectric nke isi mbipụta, ọ na-abụkarị naanị obosara obosara nke ebili mmiri na-akwọ ụgbọ mmiri nwere ike ịgbanwe iji nweta ebe kacha mma.

Ugbu a, enwere ụfọdụ nozzles nwere nnukwu ọdịda na ahịa ngwa nbipute UV. Emezigharịrị nozzle mbụ nke na-ebipụta anya 8 mm ka ọ bụrụ nnukwu ebili mmiri ka ọ bipụta 2 cm. Otú ọ dị, n'otu aka, nke a ga-ebelata ngwa ngwa nke mbipụta. N'aka nke ọzọ, mmejọ dị ka ink na-efe efe na streaking agba ga-emekwa ugboro ugboro, nke chọrọ ọkwa teknụzụ dị elu nke ndị na-emepụta ngwa nbipute UV.